tungsten carbide hot roller ring for engraving bring versatility to industries like aerospace and oil, handling critical tasks with ease. Their strength and precision make them a perfect fit for diverse needs. tyhightech’s tungsten carbide hot roller ring for engraving offer solutions for every challenge, big or small.

With options for customization, tyhightech ensures their cemented carbide works for any sector. Their experience makes them a go-to for reliable performance. Unlock new potential with tyhightech’s tungsten carbide hot roller ring for engraving.

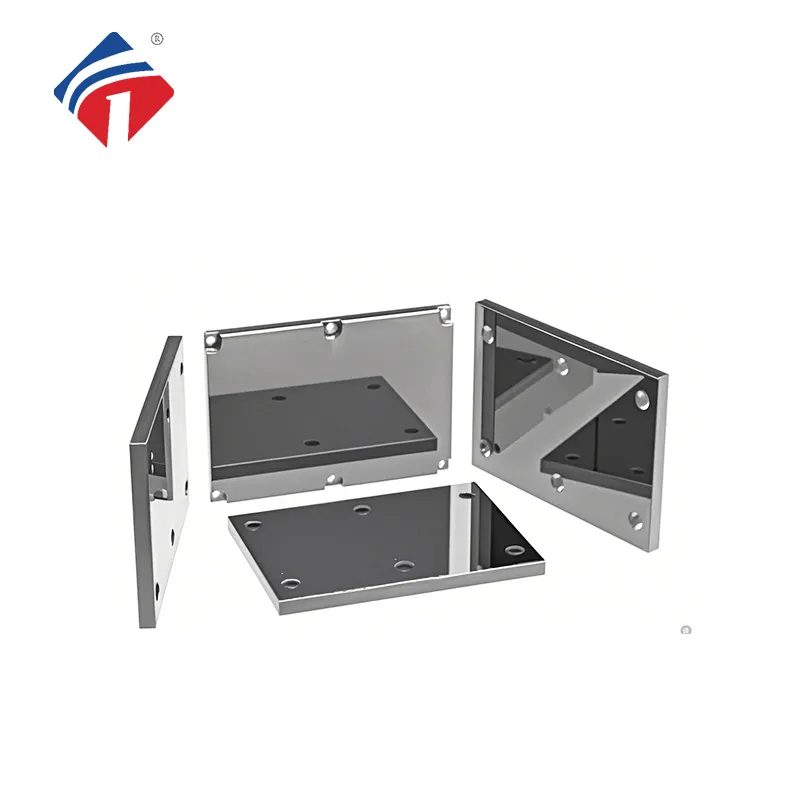

In metal forming, Cemented Carbide’s toughness excels. Rolls and dies made from this material shape steel and aluminum with precision, ideal for automotive and construction parts. Their wear resistance ensures consistent output, even in high-pressure processes. tyhightech powers your forming with tools that last.

These components handle intense forces without cracking, reducing downtime. Their smooth surfaces create flawless finishes, boosting product quality. From sheets to profiles, they deliver reliability. Choose this material to make metal forming efficient and cost-effective.

Sustainability is shaping the future of Cemented Carbide. Recyclable compositions and low-impact production are gaining traction, reducing environmental footprints. These tools will last longer, minimizing waste in mining and construction. tyhightech leads with eco-conscious designs, ensuring you roll green without losing strength. It’s a win-win for your business and the planet.

Looking ahead, expect hybrid binders that enhance toughness while staying recyclable. These advancements will power tools for everything from rebar to circuit boards, keeping performance high and waste low. Embrace this green revolution for a future where quality and sustainability go hand in hand.

Sustainability meets performance with Cemented Carbide. tyhightech’s tools are crafted with eco-conscious methods, lowering emissions. Their durability reduces the need for new tools, conserving resources in metal forming and mining. It’s a green way to keep your operations running smoothly.

These tools resist wear, cutting energy use and scrap. Their recyclable design supports a circular economy, making disposal responsible. Choose this eco-friendly path to produce high-quality parts with a conscience, knowing you’re helping the planet.

tungsten carbide hot roller ring for engraving are prized for their incredible hardness and wear resistance, making them perfect for tough industrial tasks. Built from tungsten carbide particles fused with a metallic binder, they shine in cutting, drilling, and heavy-duty applications. tyhightech offers a broad selection of these products, crafted with precision to ensure top-notch performance even in extreme conditions.

In sectors like mining and manufacturing, tyhightech’s tungsten carbide hot roller ring for engraving provide outstanding durability and reliability. These expertly designed tools cut downtime and ramp up productivity, giving businesses a competitive edge. Trust tyhightech for innovative solutions that redefine cemented carbide excellence.

Q: What are tungsten carbide hot roller ring for engraving made of?

A: tungsten carbide hot roller ring for engraving are composite materials consisting of hard carbide particles, typically tungsten carbide (WC), bonded with a metallic binder, usually cobalt (Co). The carbide particles deliver exceptional hardness and wear resistance, while the binder provides toughness and shock resistance, creating a durable material suited for demanding industrial uses.

Q: What are the main applications of tungsten carbide hot roller ring for engraving?

A: These products excel in industries requiring durability and wear resistance. They are widely used in cutting tools for machining metals, wood, and plastics; mining and drilling equipment for oil and gas exploration; wear parts in automotive and aerospace sectors; and dies and molds for manufacturing. Their strength and precision make them essential for high-stress tasks.

Q: How do tungsten carbide hot roller ring for engraving compare to materials like steel or ceramics?

A: Compared to steel, cemented carbide offers greater hardness and wear resistance, ideal for tough conditions. Ceramics may be harder but are more brittle, lacking the toughness that the binder in cemented carbide provides. This combination of strength and resilience often makes it a superior choice for applications involving heavy wear and impact.

Q: What are the different grades of tungsten carbide hot roller ring for engraving?

A: Various grades exist, each designed for specific purposes. Differences stem from carbide particle size, binder content, and carbide type. Fine-grain grades suit precision cutting tools for their sharpness, while coarse-grain options are preferred for rugged tasks like mining, where impact resistance is key. Matching the grade to the job optimizes performance.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved