1) The specification of the cemented carbide roller

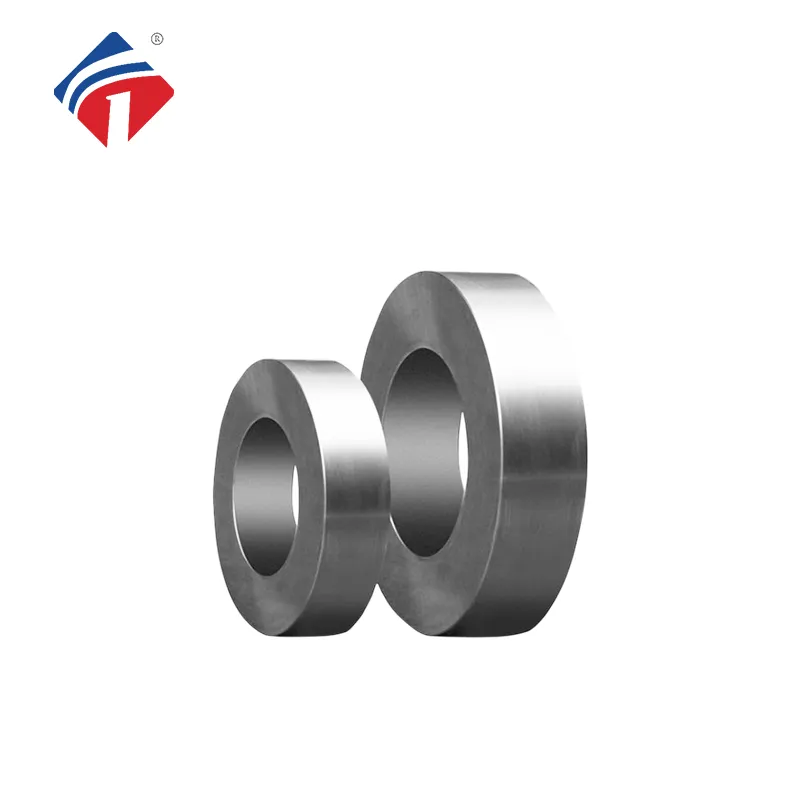

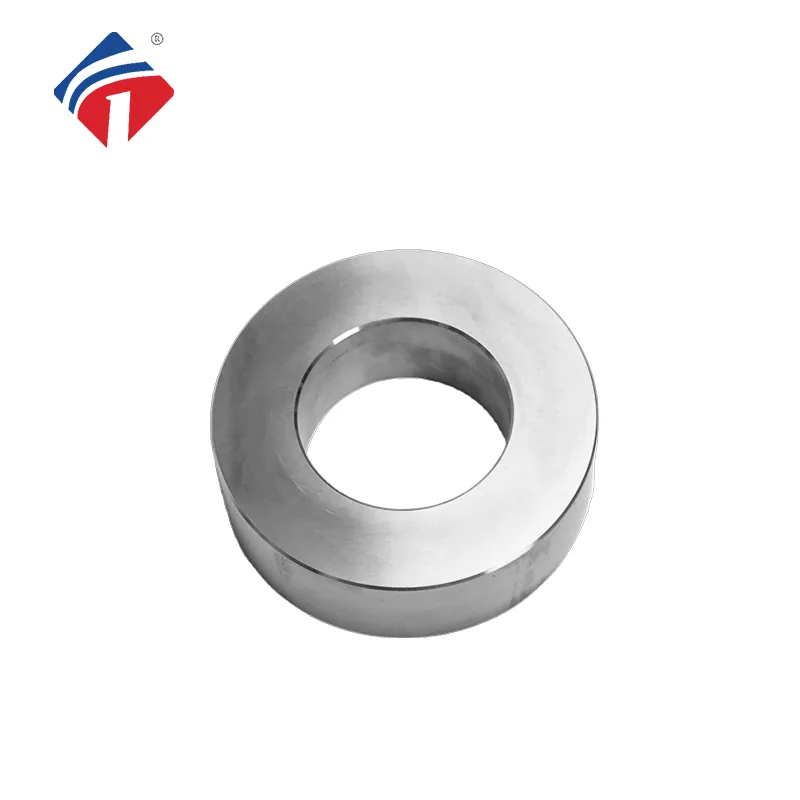

Polishing Roller

Product Information

* Material: WC, Metallic binder (Cobalt, Nickel, etc.)

* Roller Style: Light roller /Grooving roller/Threaded roller.

* Application: Pre-finishing & Finishing Rolling In Rolling Mill

* Types of Rolling: Hot Rolling(High-Temperature),Cold Rolling(Room temperature)

* Surface: Polishing

* Advantage: exceptional hardness, high wear resistance, high resistance, and durability

* Certification: ISO Certificate

* Other Services: OEM/ODM

Description

Technical Parameter

|

Rang of O.D. |

Rang of I.D. |

Rang of height |

|

145-330 |

87-260 |

45-130 |

2) The tolerances allowable for the outer diameter, inner diameter, and height of roll rings

|

Precision Index |

1 |

2 |

3 |

4 |

Special requirements |

|

O.D. (±) |

0.02 |

0.05 |

0.10 |

0.15 |

|

|

0.D. (±) |

IT 5 |

IT6 |

IT7 |

IT8 |

|

|

Height(-) |

0.03 |

0.1 |

0.20 |

0.5 |

3) The allowable deviation of carbide roll rings

a. Radial runout of groove: ≤0.013mm

b. Radial runout of geriphery: ≤0.013mm

c. End face runout: ≤0.02mm

d. End face planeness: ≤0.01mm

e. End face parallelism: ≤0.01mm

f. Inner hole cylindericity: ≤0.01m

4) Roughness of carbide rolls

Inner hole roughness: 0.4μm

Periphery roughness: 0.4μm

End face roughness: 0.4μm

Note:

The allowable deviation in external diameter, diameter, and height is to be determined based on the customers' needs.

We can customize your size & materials according to the drawings provided by customers.

Service Display

Pre-sales:

We provide professional recommendations based on customers’ actual working conditions and specific requirements. Custom design and development are available to meet individual needs. During special circumstances such as the epidemic, we also offer remote inspection and technical assistance.

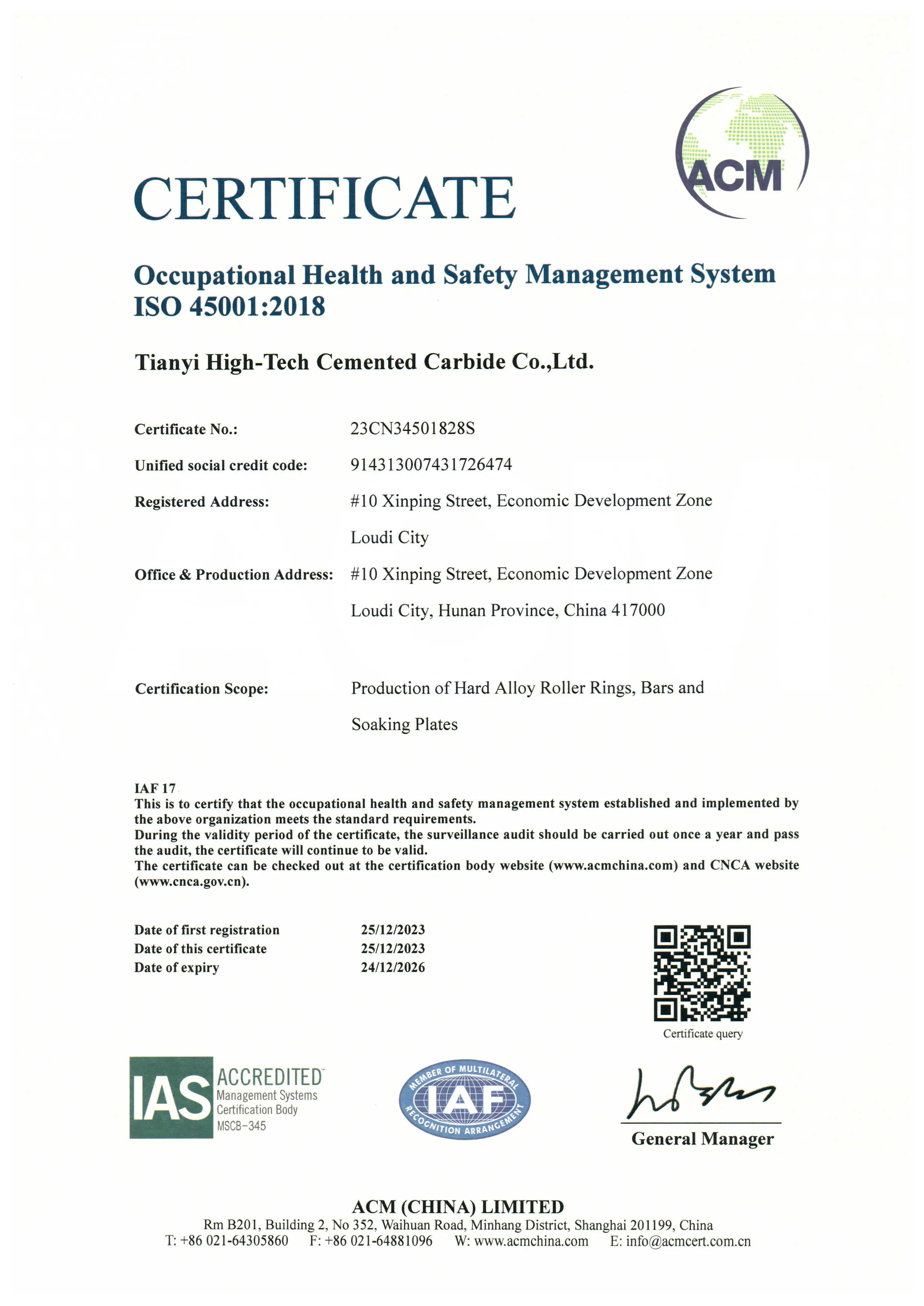

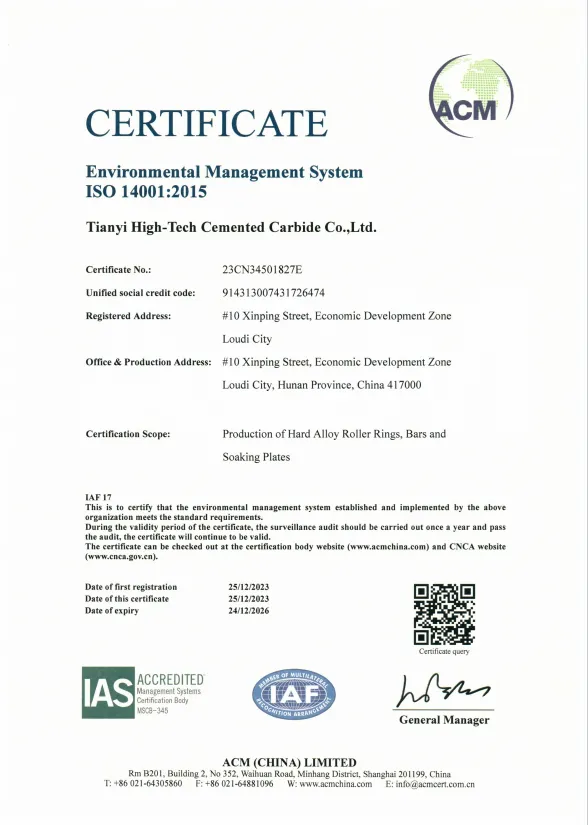

Strict quality control:

Every stage—from raw material selection to production and final inspection—is strictly monitored. All performance parameters are thoroughly tested, and our dedicated QC team ensures full compliance with quality standards.

After-sales service:

We guarantee product quality and promptly address any problems or concerns that may occur.

ISO Certificate

If you'd like to know more details, please find the relevant documents through the following links or download them from the homepage.

① The table of specifications of the finished carbide roll blanks

② Recommended applications of grades for carbide roll rings

③ Table of grades and properties of carbide roll rings and related data

INQUIRY

Related product categories

- hard alloy roll rings for cold rolling

- China carbide roll rings for steel mills

- high-durability roller rings for steel mills

- carbide roll rings with excellent thermal conductivity for hot rolling

- cemented carbide roll rings for bar mills

- supplier of roll rings for steel industry

- carbide rolls blanks for roughing

- cemented carbide bits for grooving

- cemented carbide cutter head for slotting

- mill cutter

- cemented tungsten carbide factory

- milling cutter bits

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de