Experience runs deep at tyhightech, and our supplier of roll rings for roughing stands prove it. Decades of know-how shape these reliable components, blending tradition with today’s tech.

Lean on tyhightech’s proven track record. Our supplier of roll rings for roughing stands carry a legacy of trust and excellence. Choose a name you can believe in.

For precision rolling in the electronics industry, tyhightech’s supplier of roll rings for roughing stands offer unmatched accuracy. These rings produce ultra-thin metal strips for components like connectors and circuit boards. Their fine grain structure ensures smooth surfaces and tight tolerances, critical for high-tech applications.

Tyhightech’s roll rings are the cornerstone of precision rolling. Their durability and precision reduce defects, ensuring top-quality output. Manufacturers rely on tyhightech to deliver tools that meet the exacting demands of electronics production, driving innovation with every roll.

Sustainability is reshaping the industry, and tyhightech’s supplier of roll rings for roughing stands are riding the wave. Recyclable materials and eco-conscious production methods are in demand, reducing waste without sacrificing strength. These rings last longer, cutting down on replacements and environmental impact. tyhightech blends green practices with top performance, making it easy to roll sustainably. Embrace this trend and show the world your commitment to a cleaner future.

Sustainability meets strength in rolling technology. supplier of roll rings for roughing stands from tyhightech use eco-conscious production methods, reducing carbon footprints while delivering top performance. Their exceptional durability extends service life, cutting down on raw material use and waste. It’s a smart choice for manufacturers who want to balance quality with environmental responsibility.

These rings are built to last, handling tough tasks like hot rolling with ease. By reducing replacements, they save energy and resources, making your operations leaner and greener. Their precision ensures consistent output, minimizing scrap. Choose these sustainable tools to roll out a brighter, eco-friendly future for your industry.

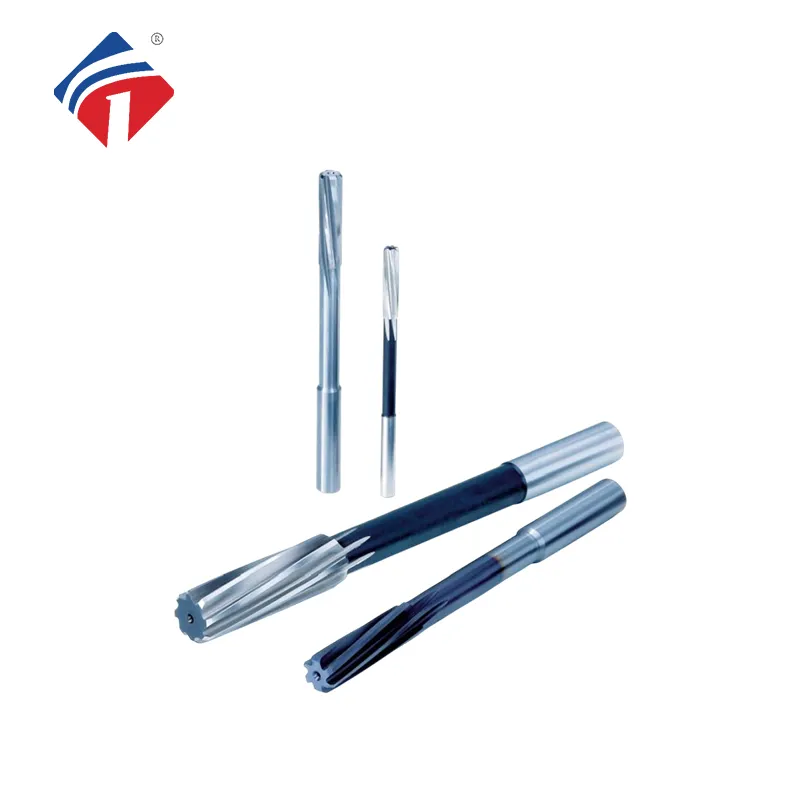

In the demanding world of metal rolling, tyhightech’s supplier of roll rings for roughing stands shine with exceptional durability. Built to endure extreme pressures and heat, they deliver reliable performance over long periods. Their tough composition cuts down on wear, meaning fewer replacements and less downtime for your operations.

Opt for tyhightech and secure top-tier quality. These roll rings are made with cutting-edge techniques, ensuring precision in every use. Discover a product that surpasses expectations and boosts your efficiency, giving you an edge in the industry.

Q: How are these components manufactured?

A: They are produced through a process of powder metallurgy, involving pressing and sintering to achieve a dense, durable structure.

Q: Do they require special maintenance?

A: Minimal upkeep is needed due to their inherent toughness, though regular inspection for wear ensures optimal performance.

Q: What happens if these rings wear out?

A: Worn rings can often be re-ground or refurbished, extending their usability before a full replacement is necessary.

Q: Are they environmentally friendly?

A: Their long service life reduces waste, and some manufacturers use recyclable materials in production, supporting sustainability efforts.

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

Although the initial cost is higher, the long lifespan and reduced replacement frequency make these rolls a cost-effective solution.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide detailed information about your cemented carbide rolls, including specifica...

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

Copyright © Tian Yi All Rights Reserved