Experience runs deep at tyhightech, and our how to select carbide roll rings for alloy steel rolling prove it. Decades of know-how shape these reliable components, blending tradition with today’s tech.

Lean on tyhightech’s proven track record. Our how to select carbide roll rings for alloy steel rolling carry a legacy of trust and excellence. Choose a name you can believe in.

In the production of rebar for construction, tyhightech’s how to select carbide roll rings for alloy steel rolling deliver unmatched reliability. These rings endure the stress of rolling textured steel, maintaining precise patterns for strong, durable rebar. Their high wear resistance ensures consistent performance, even in high-volume production, making them a favorite in the construction industry.

Build stronger with tyhightech’s roll rings, designed to meet the demands of rebar manufacturing. Their robust construction minimizes downtime, while their precision ensures high-quality output. tyhightech’s commitment to durability makes these rings a trusted choice for producing rebar that meets rigorous industry standards.

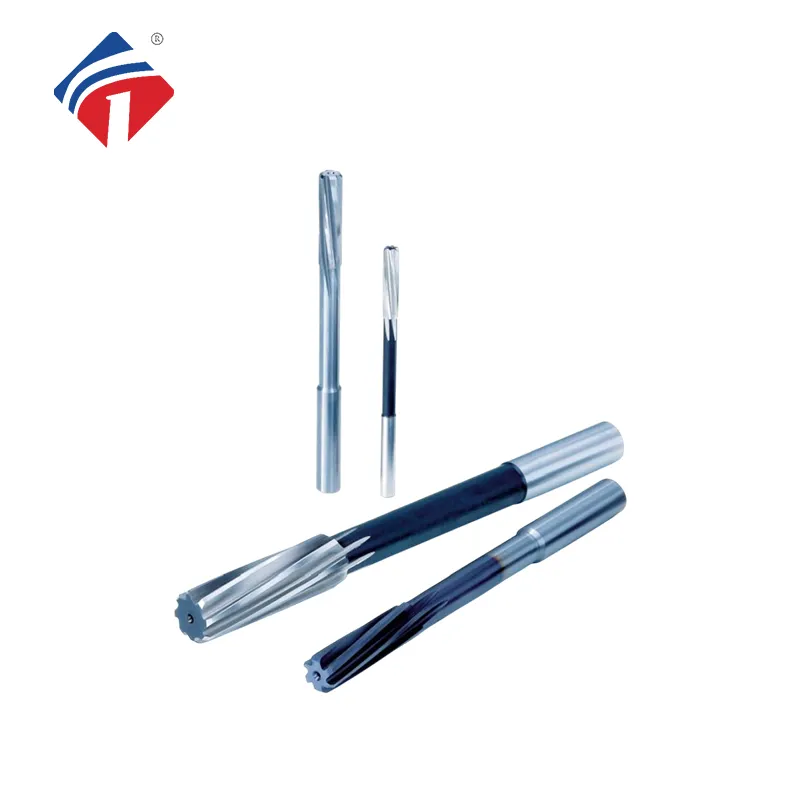

Precision is the name of the game, and tyhightech’s how to select carbide roll rings for alloy steel rolling are at the forefront. Ultra-fine grain structures are trending, delivering pinpoint accuracy for thin-gauge rolling in electronics and aerospace. These rings ensure flawless finishes, meeting the tightest tolerances. Manufacturers love the consistency, and tyhightech’s innovative designs make it happen. Stay ahead with tools that turn precision into your competitive edge, all while keeping things simple and reliable.

Make a difference with eco-smart rolling solutions. tyhightech’s how to select carbide roll rings for alloy steel rolling are designed for longevity, reducing the need for frequent replacements and conserving resources. Made with recyclable carbide, they support a circular economy, letting you roll with confidence while staying green. It’s sustainability that doesn’t skimp on strength or precision.

These rings handle intense rolling tasks, from steel bars to fine wires, with minimal wear. Their robust build cuts down on maintenance, saving energy and costs. Recycling options make disposal easy and eco-friendly. Pick these rings to boost your production while keeping your environmental impact low and your results high.

Support doesn’t stop at purchase with tyhightech. Our how to select carbide roll rings for alloy steel rolling come with full after-sales care, from setup help to ongoing advice. We’ve got your back.

Choose tyhightech for lasting teamwork. Our roll rings ensure smooth running with expert assistance always available. Rest easy knowing help is near.

Q: Are they suitable for all rolling mills?

A: They work with most systems, though adjustments to cooling or lubrication might be needed for optimal integration.

Q: What’s the price range for these roll rings?

A: While they cost more initially than traditional materials, their longevity and reduced upkeep expenses often offset the investment.

Q: How do they contribute to long-term savings?

A: Their extended lifespan and minimal maintenance needs cut down on replacement frequency and operational interruptions, lowering overall costs.

Q: Do manufacturers provide warranties for them?

A: Most suppliers offer warranties covering material or manufacturing defects, though terms differ by provider.

These cemented carbide rolls are incredibly durable and have significantly improved our production efficiency.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

Do you provide after-sales support or maintenance services for cemented carbide rolls?

Copyright © Tian Yi All Rights Reserved