Experience runs deep at tyhightech, and our carbide roller rings for high-speed wire rod mills prove it. Decades of know-how shape these reliable components, blending tradition with today’s tech.

Lean on tyhightech’s proven track record. Our carbide roller rings for high-speed wire rod mills carry a legacy of trust and excellence. Choose a name you can believe in.

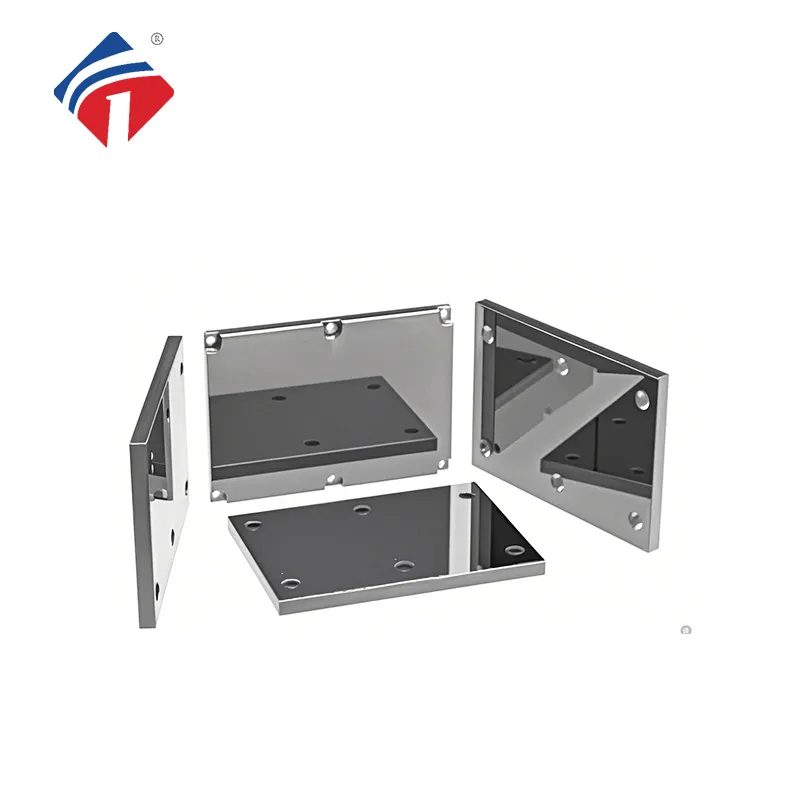

For precision rolling in the electronics industry, tyhightech’s carbide roller rings for high-speed wire rod mills offer unmatched accuracy. These rings produce ultra-thin metal strips for components like connectors and circuit boards. Their fine grain structure ensures smooth surfaces and tight tolerances, critical for high-tech applications.

Tyhightech’s roll rings are the cornerstone of precision rolling. Their durability and precision reduce defects, ensuring top-quality output. Manufacturers rely on tyhightech to deliver tools that meet the exacting demands of electronics production, driving innovation with every roll.

Smart manufacturing is changing the game, and tyhightech’s carbide roller rings for high-speed wire rod mills are part of it. Sensors embedded in rings to monitor wear and performance are gaining buzz, helping predict maintenance and avoid downtime. These smart tools keep production smooth and efficient. tyhightech is embracing this tech-forward trend, offering rings that blend brains with brawn. Step into the future of rolling with tools that think as hard as they work.

Sustainable rolling starts here. tyhightech’s carbide roller rings for high-speed wire rod mills are crafted with eco-friendly materials, minimizing environmental impact. Their long-lasting design reduces the need for new tools, conserving resources and cutting waste. It’s a simple way to make your production greener while keeping performance top-notch.

These rings tackle tough jobs like rebar rolling with ease, maintaining precision and strength. Their durability lowers maintenance energy, and recycling programs make them a responsible choice. With these rings, you’re investing in a sustainable future that doesn’t compromise on quality—roll smart, roll green.

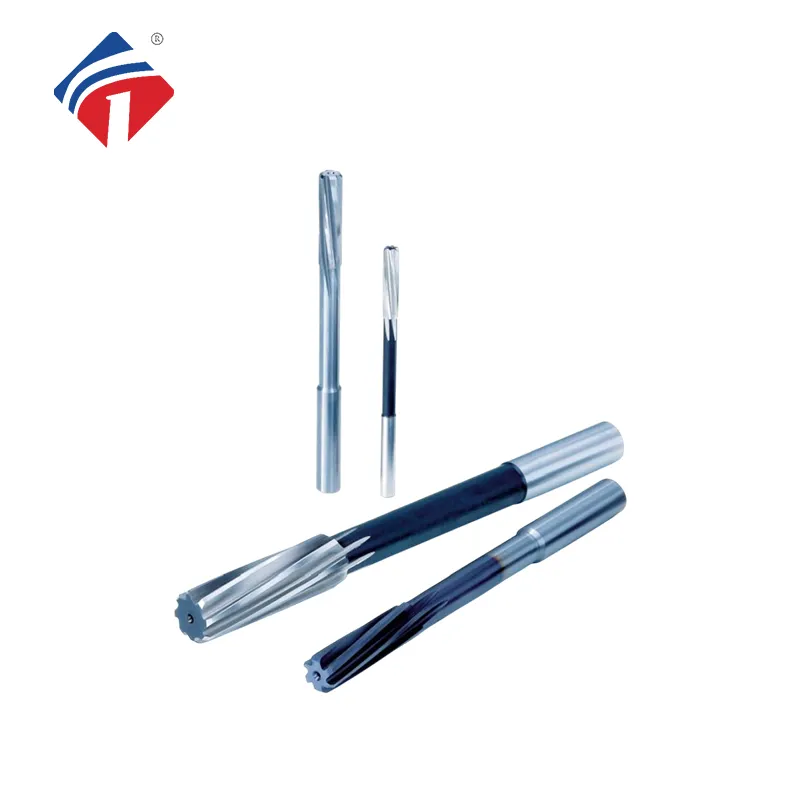

Crafted with care, tyhightech’s carbide roller rings for high-speed wire rod mills boast precision engineering. Every detail is perfect, from size to finish, ensuring top-tier rolling output. Accuracy drives their success.

At tyhightech, details matter. Our roll rings reflect strict quality and skill, offering reliability you can trust. Take your operations to new heights with precision-made components.

Q: How are these components manufactured?

A: They are produced through a process of powder metallurgy, involving pressing and sintering to achieve a dense, durable structure.

Q: Do they require special maintenance?

A: Minimal upkeep is needed due to their inherent toughness, though regular inspection for wear ensures optimal performance.

Q: What happens if these rings wear out?

A: Worn rings can often be re-ground or refurbished, extending their usability before a full replacement is necessary.

Q: Are they environmentally friendly?

A: Their long service life reduces waste, and some manufacturers use recyclable materials in production, supporting sustainability efforts.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved