Buy with assurance thanks to tyhightech’s replacement roll rings for seamless tube mills and their solid warranty. We stand by our quality, protecting your investment every day.

Choose tyhightech for certainty. Our replacement roll rings for seamless tube mills come with a guarantee of excellence. Rest easy with a brand that delivers.

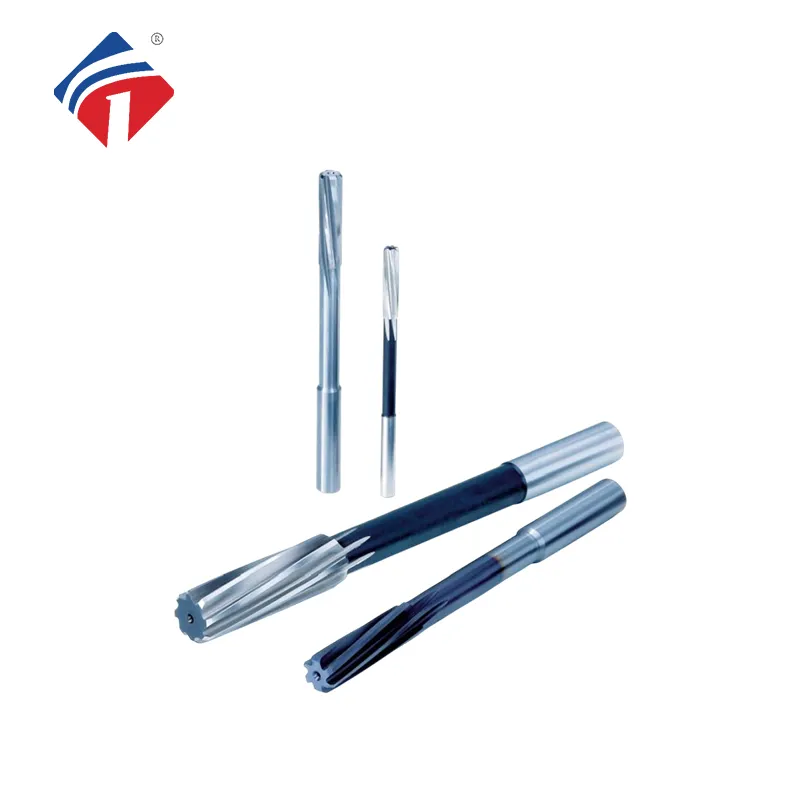

In steel rolling mills, tyhightech’s replacement roll rings for seamless tube mills shine as critical components for producing high-quality steel products. Their exceptional hardness and wear resistance allow them to withstand the intense pressure and friction of hot and cold rolling processes. These rings maintain precise dimensions, ensuring consistent output for steel bars, sheets, and wires. Used in high-speed rolling operations, they reduce downtime by resisting cracking and deformation, even under extreme conditions. tyhightech delivers reliability that keeps production lines running smoothly, making these rings a top choice for steel manufacturers worldwide.

Boost your steel production with tyhightech’s expertly crafted roll rings. Designed for durability, they handle the toughest alloys, delivering flawless finishes and minimizing maintenance costs. Their thermal stability ensures performance in high-heat environments, while their robust construction extends service life. From structural beams to fine wires, tyhightech’s rings provide the precision and strength needed to excel in demanding steel rolling applications.

Cost efficiency is a big deal, and tyhightech’s replacement roll rings for seamless tube mills are setting the pace. Longer-lasting rings with improved wear resistance are trending, cutting down on replacements and maintenance. This means more uptime and lower costs for manufacturers. tyhightech delivers value without compromising quality, making it easy to stay budget-friendly. Hop on this trend to keep your production lean and profitable.

Make a difference with eco-smart rolling solutions. tyhightech’s replacement roll rings for seamless tube mills are designed for longevity, reducing the need for frequent replacements and conserving resources. Made with recyclable carbide, they support a circular economy, letting you roll with confidence while staying green. It’s sustainability that doesn’t skimp on strength or precision.

These rings handle intense rolling tasks, from steel bars to fine wires, with minimal wear. Their robust build cuts down on maintenance, saving energy and costs. Recycling options make disposal easy and eco-friendly. Pick these rings to boost your production while keeping your environmental impact low and your results high.

Whether it’s steel or aluminum, tyhightech’s replacement roll rings for seamless tube mills adapt effortlessly. They handle various metals with consistent precision across conditions. Versatility makes them a must-have in any plant.

Flexibility defines tyhightech. Our roll rings meet diverse industry demands, ready for any challenge. Experience adaptable performance that keeps you competitive.

Q: What steps are involved in their creation?

A: The process starts with mixing tungsten carbide powder with a binder, shaping it under pressure, and sintering it to produce a hard, precise component.

Q: How is their quality ensured?

A: Advanced testing methods, like ultrasonic inspections and dimensional verification, are used to guarantee consistency and reliability.

Q: What’s the best way to confirm their quality before buying?

A: Choose suppliers with a strong reputation, industry certifications, and detailed product specifications to ensure top-notch quality.

Q: Where are they available for purchase?

A: They can be sourced from manufacturers, distributors, or trusted online platforms specializing in industrial components.

These rolls perform exceptionally well under high-temperature conditions.

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

Copyright © Tian Yi All Rights Reserved