Go green with tyhightech’s china cutting tool distributors, made to last and cut waste. Sustainable production methods reduce their environmental impact while delivering top performance.

tyhightech helps you mill responsibly, aligning durability with eco-friendly goals. Build a better tomorrow with tools that care for the planet.

Let's chat about the cool ways china cutting tool distributors revolutionize tasks across the board. Perfect for engraving logos on promotional items or milling gears in robotics, these cutters bring precision to the forefront. In the medical field, they shape implants with life-saving accuracy, and for artists, they etch stunning sculptures from stone. Plastics fabrication? They slice through with ease for custom packaging. Tyhightech delivers top-notch picks that enhance reliability without overcomplicating things. Wood routing for signage becomes a joy, yielding crisp results every time. Imagine slashing production downtime and amping up creativity—these tools do just that. Convince yourself: integrating them means smoother sails in any project, turning challenges into triumphs effortlessly!

Peek into tomorrow's machining world, where china cutting tool distributors evolve into smarter, more efficient powerhouses. Imagine tools infused with AI that predict wear and adjust speeds on the fly, slashing downtime and boosting precision. Hybrid tech blends additive and subtractive methods, crafting complex parts from advanced composites with ease. Sustainability takes center stage too—eco-friendly coatings reduce waste while extending tool life. Brands like tyhightech are leading the charge with innovative designs that fit seamlessly into modern setups. Multi-axis capabilities will handle intricate geometries effortlessly, perfect for aerospace and medical fields. As robotics integrate deeper, expect seamless automation that makes pro-level results accessible to all. Why wait? Embracing these advancements means smoother operations, cost savings, and standout quality. The future's bright—gear up and watch your projects soar!

Sustainability meets performance with Cemented Carbide. tyhightech’s tools are crafted with eco-conscious methods, lowering emissions. Their durability reduces the need for new tools, conserving resources in metal forming and mining. It’s a green way to keep your operations running smoothly.

These tools resist wear, cutting energy use and scrap. Their recyclable design supports a circular economy, making disposal responsible. Choose this eco-friendly path to produce high-quality parts with a conscience, knowing you’re helping the planet.

Polish your work to perfection with tyhightech’s china cutting tool distributors for finishing. These precision tools create smooth, stunning surfaces, critical for electronics and luxury goods where every detail counts.

tyhightech’s finishing end mills use micro-grain carbide and clever geometries for pinpoint accuracy. Low-friction coatings keep heat low, protecting your tools and parts. Achieve craftsmanship that turns heads with these standout performers.

Q: What purposes do china cutting tool distributors serve in machining?

A: These tools are essential for precision cutting tasks like milling, slotting, and contouring across industries such as aerospace, automotive, and medical. They shape materials like metals and plastics, delivering intricate designs and smooth finishes for components like engine parts or molds.

Q: What materials are commonly used to make these cutting tools?

A: They’re often crafted from carbide, high-speed steel (HSS), or cobalt. Carbide provides exceptional hardness and heat resistance for tough jobs, HSS offers flexibility and affordability for general use, and cobalt strikes a balance for medium-duty applications.

Q: What varieties of these tools exist?

A: You’ll find square end mills for flat surfaces, ball nose end mills for curved shapes, and corner radius end mills for durability in high-speed cuts. Each type suits specific machining needs, ensuring precision and efficiency.

Q: How do coatings enhance their performance?

A: Coatings like TiN, TiCN, and AlTiN reduce friction and heat, boosting durability. They help the tools stay sharp longer, especially when cutting hard or abrasive materials, and improve performance in high-temperature conditions.

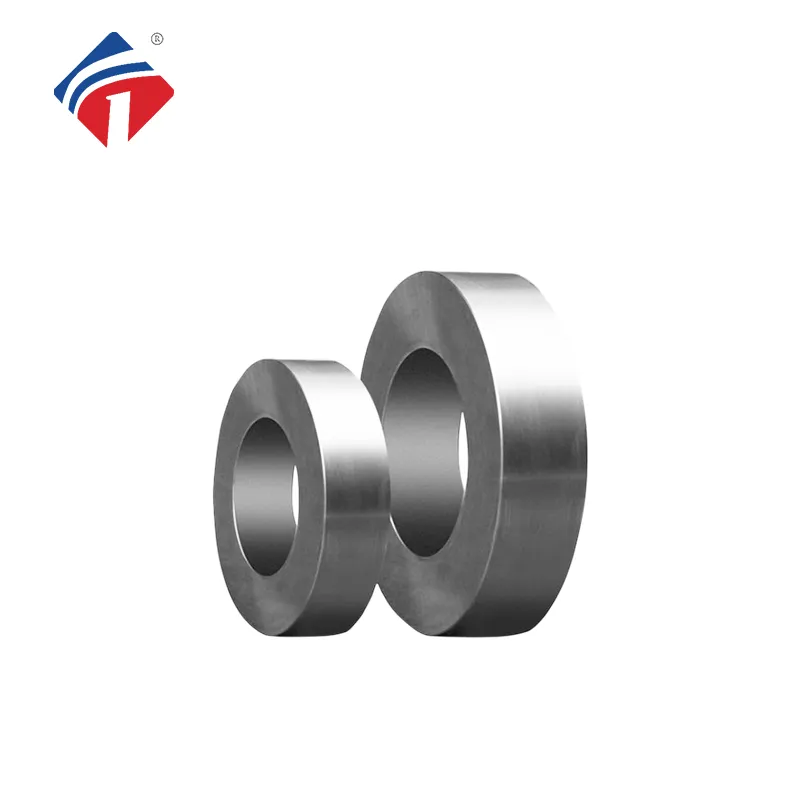

These cemented carbide rolls are incredibly durable and have significantly improved our production efficiency.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

Do you offer customized cemented carbide rolls? We require specific dimensions and coatings for our ...

Copyright © Tian Yi All Rights Reserved