cemented carbide tools for finishing evolve with innovation, and tyhightech leads the charge with fresh ideas. Their research team crafts cutting-edge solutions that redefine performance. tyhightech’s cemented carbide tools for finishing keep you ahead in a fast-moving world.

Partnering with tyhightech means tapping into progress and reliability. Their advanced cemented carbide offerings meet today’s toughest demands. Stay competitive with tyhightech’s forward-looking cemented carbide tools for finishing.

In medical manufacturing, Cemented Carbide’s precision is vital. Tools like surgical blades and dental drills made from this material offer unmatched accuracy and durability. They maintain sharp edges for delicate procedures, ensuring patient safety. tyhightech crafts tools that doctors and dentists trust.

These instruments resist corrosion and wear, performing reliably in sterile environments. Their fine edges deliver consistent results, critical for implants and prosthetics. With this material, you get precision that saves lives. Choose it to elevate your medical manufacturing to new heights.

Versatility is the future of Cemented Carbide. Multi-purpose tools that handle cutting, drilling, and forming across materials are set to shine. This flexibility simplifies toolkits and boosts efficiency in industries like electronics. tyhightech crafts these all-rounders, making your work easier and smarter. Why juggle tools when one can do it all?

Sustainable designs will also reduce waste, with recyclable materials and longer lifespans. These versatile tools will keep your production lean and green, delivering results that impress. Step into a future where one tool conquers every challenge.

Go green without compromising strength! Cemented Carbide tools from tyhightech are crafted with recyclable materials, slashing waste in industries like mining and machining. Their durability means fewer replacements, saving resources and keeping production eco-friendly. It’s a simple way to make your workshop sustainable while delivering top-notch results every time.

These tools shine in tough tasks, resisting wear to extend service life. Eco-conscious production cuts emissions, and recycling programs make disposal a breeze. Choose this solution to keep your operations lean, green, and efficient, all while crafting high-quality components with ease.

cemented carbide tools for finishing, like inserts and drill bits, are key players in manufacturing due to their cutting-edge performance. Made from a tough blend of tungsten carbide and cobalt, they last longer and stay sharp under pressure. tyhightech crafts these products with advanced tech, guaranteeing precision in every detail.

vBeyond off-the-shelf options, tyhightech offers bespoke cemented carbide tools for finishing to match your unique specs. Their skilled team works with you to enhance efficiency and results. Choose tyhightech for exceptional cemented carbide tools and unmatched support.Q: What’s the difference between Cemented Carbide and steel?

A: Cemented Carbide is harder and more wear-resistant than steel, but less flexible. Its sintered structure suits cutting and grinding, unlike steel’s ductility. Hunan Tianyi High-Tech Materials Co., Ltd. highlights Cemented Carbide’s superior properties for tough tasks.

Q: How does Cemented Carbide compare to ceramics?

A: Cemented Carbide is tougher and more impact-resistant than ceramics, though ceramics may be harder. Its metallic binder adds flexibility. Hunan Tianyi High-Tech Materials Co., Ltd. produces versatile Cemented Carbide for a range of industrial needs.

Q: Can Cemented Carbide be sharpened?

A: Yes, Cemented Carbide can be sharpened, though it requires specialized tools due to its hardness. Its edge retention is exceptional. Hunan Tianyi High-Tech Materials Co., Ltd. ensures its Cemented Carbide maintains precision over time.

Q: Is Cemented Carbide brittle?

A: While Cemented Carbide is very hard, it’s not brittle due to the metallic binder, which adds toughness. It resists cracking under impact. Hunan Tianyi High-Tech Materials Co., Ltd. crafts balanced Cemented Carbide for durability and strength.

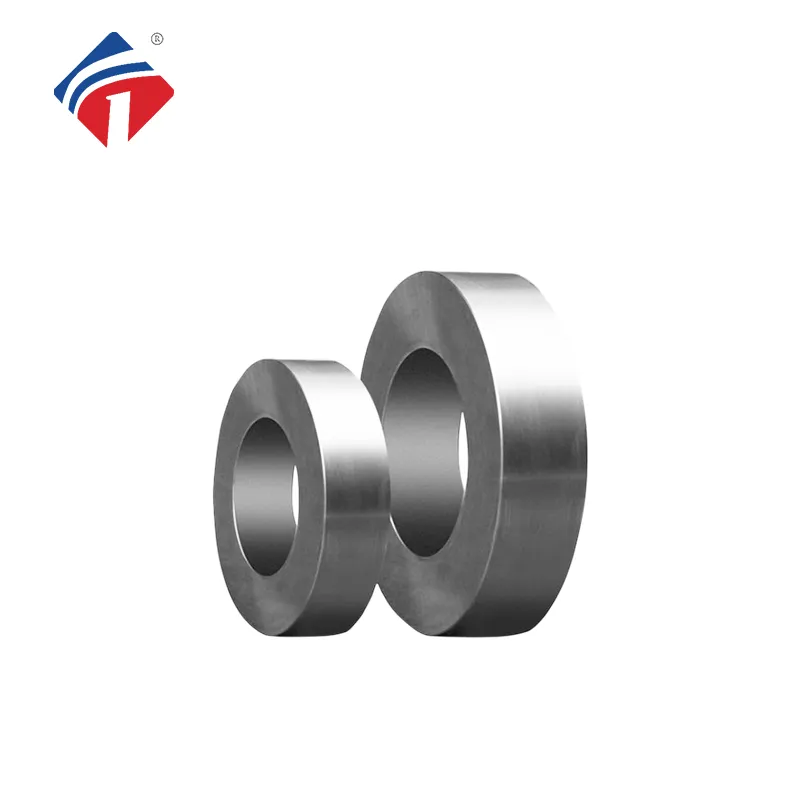

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

The precision of these carbide rolls is outstanding. They consistently deliver accurate results, ensuring high-quality output for our products.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

Copyright © Tian Yi All Rights Reserved