cemented carbide rings for mill rolls for plastics cutting may cost more upfront, but their longevity and efficiency pay off big. They cut downtime and stretch tool life, saving you money over time. tyhightech’s cemented carbide rings for mill rolls for plastics cutting are built to maximize these gains, offering unbeatable value.

With tyhightech, you get cemented carbide that powers up your operations while keeping costs down. Their smart designs are perfect for businesses aiming to optimize. Invest in tyhightech’s cemented carbide rings for mill rolls for plastics cutting for a brighter bottom line.

Mining gets a boost with Cemented Carbide’s durability. Drill bits and cutting picks crafted from this material chew through hard rock and ore, standing up to abrasive conditions. Used in tunneling and extraction, they keep operations moving without frequent pauses. tyhightech brings reliability to the toughest environments, making mining smarter and faster.

These tools resist wear and impact, extending service life and cutting costs. Whether it’s coal, gold, or limestone, you’ll dig deeper with less hassle. Their strength ensures steady performance, even underground. Embrace this rugged solution to keep your mining projects on track and thriving.

Cemented Carbide is headed for a lightweight revolution. New formulations will make tools stronger yet lighter, ideal for aerospace and automotive applications. These leaner tools will handle high-stress tasks without bulk, boosting efficiency. tyhightech is crafting these game-changers, keeping your operations nimble and strong. Get ready to soar with tools that pack a punch.

Expect eco-smart designs too, with recyclable materials cutting waste. These advancements will streamline production while keeping performance top-notch. The future’s all about doing more with less, and this material’s ready to lead the way.

Sustainability is easy with Cemented Carbide’s long-lasting performance. These tools, made with recyclable carbide, reduce the need for frequent replacements, conserving materials. tyhightech’s designs support a circular economy, making your production greener. It’s a smart choice for manufacturers who want quality and eco-responsibility in one package.

From cutting tools to wear parts, these solutions handle high-stress jobs while minimizing waste. Low-energy manufacturing and recyclable binders keep the environmental impact low. Pick this path to roll out sustainable, high-performance products that impress.

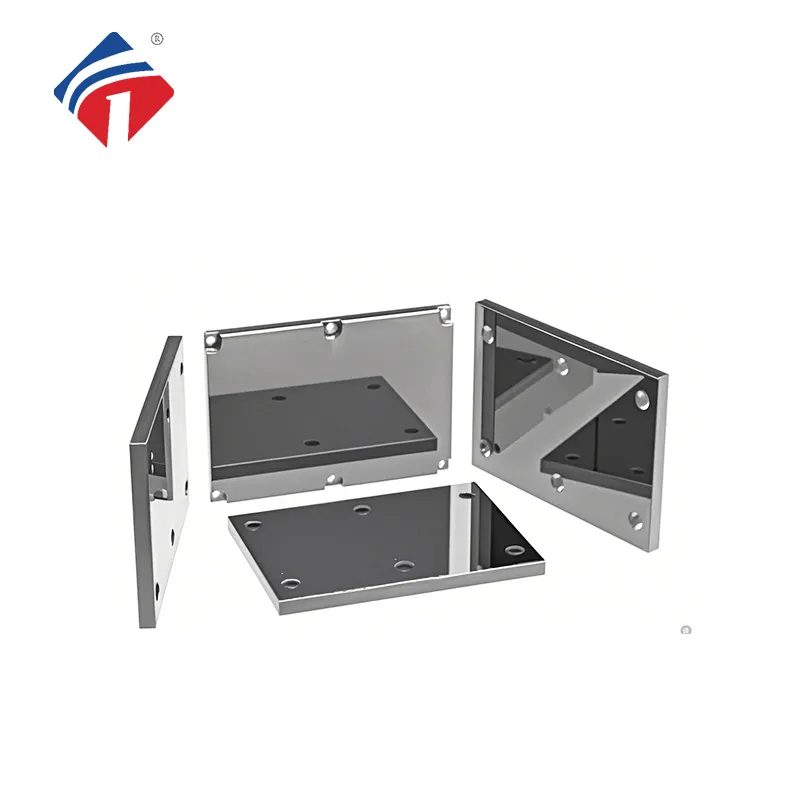

cemented carbide rings for mill rolls for plastics cutting, like inserts and drill bits, are key players in manufacturing due to their cutting-edge performance. Made from a tough blend of tungsten carbide and cobalt, they last longer and stay sharp under pressure. tyhightech crafts these products with advanced tech, guaranteeing precision in every detail.

vBeyond off-the-shelf options, tyhightech offers bespoke cemented carbide rings for mill rolls for plastics cutting to match your unique specs. Their skilled team works with you to enhance efficiency and results. Choose tyhightech for exceptional cemented carbide tools and unmatched support.Q: What is the lifespan of cemented carbide rings for mill rolls for plastics cutting?

A: Durability depends on usage, grade, and conditions, but these products generally outlast traditional materials like steel due to their wear resistance. With proper care, such as regular sharpening, they can endure significantly longer, cutting downtime and replacement costs in high-wear settings.

Q: Are cemented carbide rings for mill rolls for plastics cutting environmentally friendly?

A: Their long lifespan reduces waste, making them more sustainable than some alternatives. Many can also be recycled, with programs available to reclaim and reuse the materials. This lowers the environmental footprint by decreasing the demand for new raw materials.

Q: How do I maintain and care for cemented carbide rings for mill rolls for plastics cutting?

A: Clean them regularly to remove debris, sharpen as needed to preserve performance, and store in a dry, cool place to prevent corrosion. Avoid dropping or excessive impacts to prevent chipping. These steps help maintain their effectiveness over time.

Q: What are the latest advancements in cemented carbide technology?

A: Innovations include ultrafine grain sizes for better hardness and wear resistance, new binders for enhanced toughness, and advanced coatings like diamond-like carbon (DLC) to boost tool life. These developments expand their capabilities in challenging applications.

The precision of these carbide rolls is outstanding. They consistently deliver accurate results, ensuring high-quality output for our products.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved