cemented carbide cold roller for wood cutting may cost more upfront, but their longevity and efficiency pay off big. They cut downtime and stretch tool life, saving you money over time. tyhightech’s cemented carbide cold roller for wood cutting are built to maximize these gains, offering unbeatable value.

With tyhightech, you get cemented carbide that powers up your operations while keeping costs down. Their smart designs are perfect for businesses aiming to optimize. Invest in tyhightech’s cemented carbide cold roller for wood cutting for a brighter bottom line.

Mining gets a boost with Cemented Carbide’s durability. Drill bits and cutting picks crafted from this material chew through hard rock and ore, standing up to abrasive conditions. Used in tunneling and extraction, they keep operations moving without frequent pauses. tyhightech brings reliability to the toughest environments, making mining smarter and faster.

These tools resist wear and impact, extending service life and cutting costs. Whether it’s coal, gold, or limestone, you’ll dig deeper with less hassle. Their strength ensures steady performance, even underground. Embrace this rugged solution to keep your mining projects on track and thriving.

Cemented Carbide is gearing up for a high-tech makeover. Smart tools with embedded sensors are emerging, monitoring wear and performance in real-time. This means less downtime and smarter maintenance for industries like automotive. tyhightech is embracing this tech, delivering tools that think as hard as they work. Your production line’s about to get a brainy upgrade.

These intelligent tools will also use greener coatings, cutting emissions while boosting durability. Expect smoother finishes and longer lifespans, saving costs and resources. This material’s future is all about precision and planet-friendly innovation—perfect for staying ahead in a fast-moving world.

Green tools, made simple. Cemented Carbide from tyhightech uses recyclable carbide and low-energy production, reducing environmental impact. Its long lifespan cuts down on replacements, saving materials in industries like woodworking. This is sustainability that fits seamlessly into your workflow.

These tools stay sharp and strong, minimizing maintenance and waste. Recycling programs make disposal eco-friendly, closing the loop. Pick this solution to keep your production green and efficient, delivering results that make both you and the planet proud.

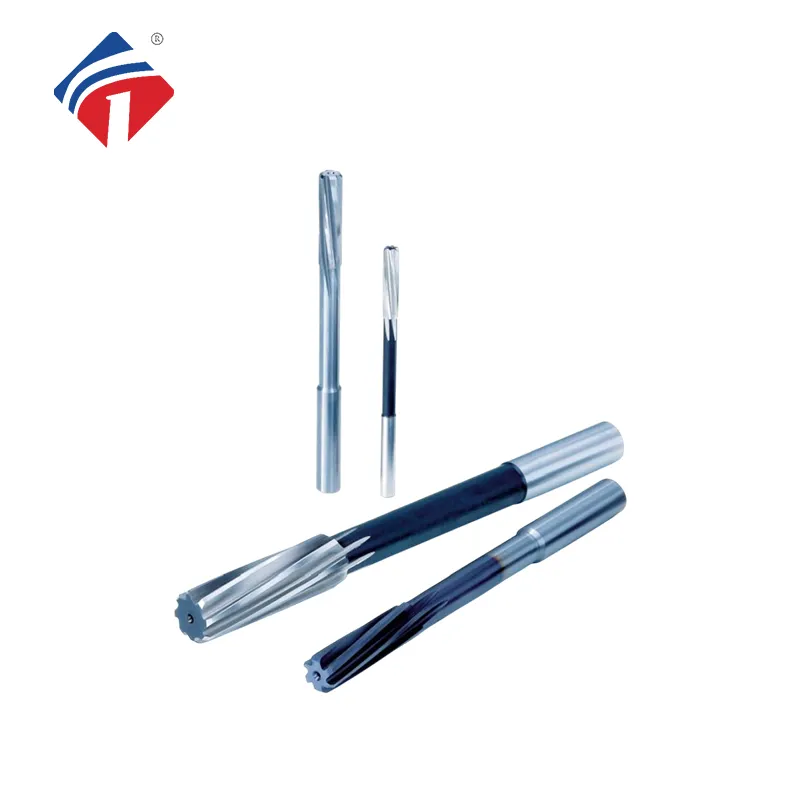

cemented carbide cold roller for wood cutting are prized for their incredible hardness and wear resistance, making them perfect for tough industrial tasks. Built from tungsten carbide particles fused with a metallic binder, they shine in cutting, drilling, and heavy-duty applications. tyhightech offers a broad selection of these products, crafted with precision to ensure top-notch performance even in extreme conditions.

In sectors like mining and manufacturing, tyhightech’s cemented carbide cold roller for wood cutting provide outstanding durability and reliability. These expertly designed tools cut downtime and ramp up productivity, giving businesses a competitive edge. Trust tyhightech for innovative solutions that redefine cemented carbide excellence.

Q: What are cemented carbide cold roller for wood cutting made of?

A: cemented carbide cold roller for wood cutting are composite materials consisting of hard carbide particles, typically tungsten carbide (WC), bonded with a metallic binder, usually cobalt (Co). The carbide particles deliver exceptional hardness and wear resistance, while the binder provides toughness and shock resistance, creating a durable material suited for demanding industrial uses.

Q: What are the main applications of cemented carbide cold roller for wood cutting?

A: These products excel in industries requiring durability and wear resistance. They are widely used in cutting tools for machining metals, wood, and plastics; mining and drilling equipment for oil and gas exploration; wear parts in automotive and aerospace sectors; and dies and molds for manufacturing. Their strength and precision make them essential for high-stress tasks.

Q: How do cemented carbide cold roller for wood cutting compare to materials like steel or ceramics?

A: Compared to steel, cemented carbide offers greater hardness and wear resistance, ideal for tough conditions. Ceramics may be harder but are more brittle, lacking the toughness that the binder in cemented carbide provides. This combination of strength and resilience often makes it a superior choice for applications involving heavy wear and impact.

Q: What are the different grades of cemented carbide cold roller for wood cutting?

A: Various grades exist, each designed for specific purposes. Differences stem from carbide particle size, binder content, and carbide type. Fine-grain grades suit precision cutting tools for their sharpness, while coarse-grain options are preferred for rugged tasks like mining, where impact resistance is key. Matching the grade to the job optimizes performance.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

These rolls perform exceptionally well under high-temperature conditions.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide detailed information about your cemented carbide rolls, including specifica...

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

Copyright © Tian Yi All Rights Reserved