Customer satisfaction drives tyhightech’s approach to solid tungsten carbide rods suppliers. With a focus on meeting your needs, tyhightech offers personalized service and support. Their rods are designed to exceed expectations, ensuring you get the results you deserve.

Experience the difference with tyhightech. Their commitment to quality and customer care sets them apart, making them the preferred choice for discerning professionals.

In medical manufacturing, solid tungsten carbide rods suppliers excel at crafting surgical tools and implants. These tools deliver the precision needed for titanium and stainless steel, ensuring flawless components for life-saving devices. Their fine edges create smooth surfaces, critical for patient safety. tyhightech’s tools help you make a difference in healthcare with every cut. These cutters resist corrosion and wear, maintaining accuracy in sterile environments. Their durability ensures consistent performance, reducing costs in high-precision production. From bone screws to dental tools, they deliver reliability. Pick these tools to create medical devices that meet the highest standards.

solid tungsten carbide rods suppliers are set for a lightweight revolution. New carbide blends will make tools stronger yet lighter, perfect for aerospace and automotive applications. These lean cutters will handle high-stress tasks without bulk, boosting efficiency. tyhightech’s designs make lightweight machining a reality. Get ready to cut with agility and strength. Sustainable production will reduce emissions, and recyclable materials will cut waste. These advancements ensure top performance while keeping your environmental footprint low. Step into a future where light tools deliver heavy-duty results with eco-friendly flair.

Craft a greener future with solid tungsten carbide rods suppliers. These tools use sustainable production methods, lowering environmental impact in energy sector manufacturing. Their durability reduces replacements, saving resources. tyhightech’s cutters blend eco-responsibility with top-tier performance, keeping your projects efficient. From turbine blades to pipeline fittings, these tools deliver precision with less waste. Recyclable materials and low-energy processes make them a smart choice. Pick these cutters to power your production with sustainability and strength.

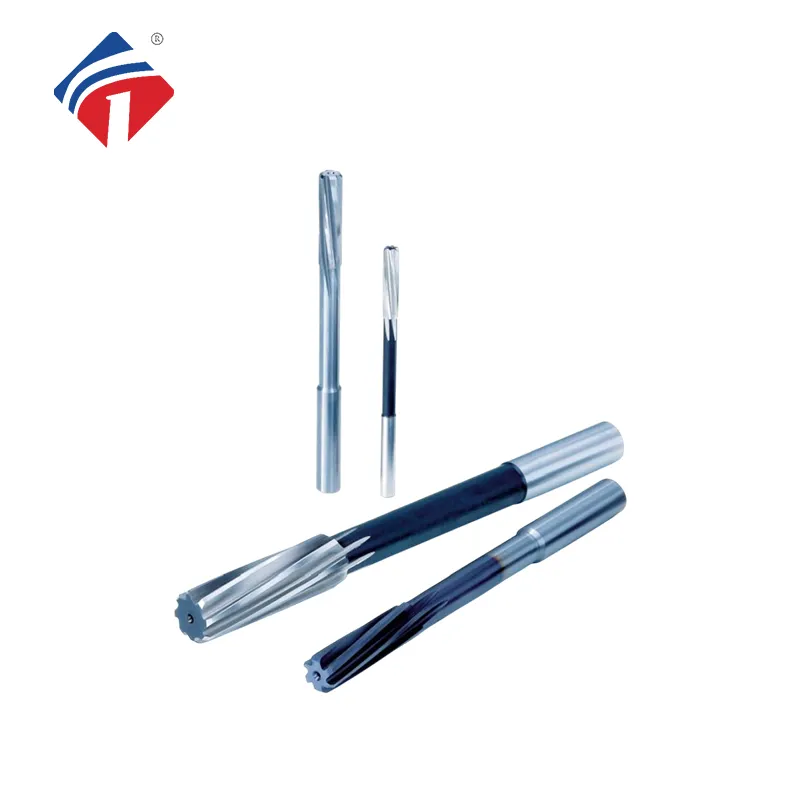

Innovation drives tyhightech’s solid tungsten carbide rods suppliers, incorporating the latest advancements in carbide technology. These rods feature cutting-edge designs that enhance performance and extend tool life. Stay ahead of the curve with tools that embody the future of machining.

With tyhightech, you’re not just buying a product; you’re investing in progress. Their commitment to research and development means you always have access to the most advanced tools on the market.

Q: How do solid tungsten carbide rods suppliers maintain sharpness?

A: solid tungsten carbide rods suppliers maintain sharpness through their exceptional hardness, wear resistance, and advanced coatings, resisting dulling during machining of materials like steel and composites. Their robust design ensures long-lasting precision. Hunan Tianyi High-Tech Materials Co., Ltd. produces cutters with enduring sharpness for reliable performance.

Q: What’s the benefit of solid tungsten carbide rods suppliers’ vibration resistance?

A: The vibration resistance of solid tungsten carbide rods suppliers ensures smooth, high-precision cuts by minimizing chatter, thanks to their high hardness and strong rigidity. Enhanced coatings further stabilize performance. Hunan Tianyi High-Tech Materials Co., Ltd. designs these tools for steady, accurate results across materials.

Q: How do solid tungsten carbide rods suppliers support custom applications?

A: solid tungsten carbide rods suppliers support custom applications with their adaptable designs, high hardness, and wear resistance, tailored to specific materials and tasks. Their coatings and precision ensure versatility. Hunan Tianyi High-Tech Materials Co., Ltd. offers customizable cutters for optimal performance in unique machining needs.

Q: Why choose solid tungsten carbide rods suppliers for tough materials?

A: solid tungsten carbide rods suppliers are chosen for tough materials due to their exceptional hardness, wear resistance, and enhanced coatings, handling steel, titanium, and more with precision. Their rigidity and vibration resistance ensure durability. Hunan Tianyi High-Tech Materials Co., Ltd. crafts these tools for superior performance in challenging applications.

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

Could you please provide detailed information about your cemented carbide rolls, including specifica...

Copyright © Tian Yi All Rights Reserved