Saving costs without cutting corners is easy with tyhightech’s roll rings for pilger mills. Their impressive durability slashes replacement expenses, while their efficiency keeps production humming. It’s a practical choice for budget-savvy manufacturers.

Make the smart move with tyhightech. Our roll rings for pilger mills offer lasting value, blending affordability with high performance. Watch your savings grow with components built to last.

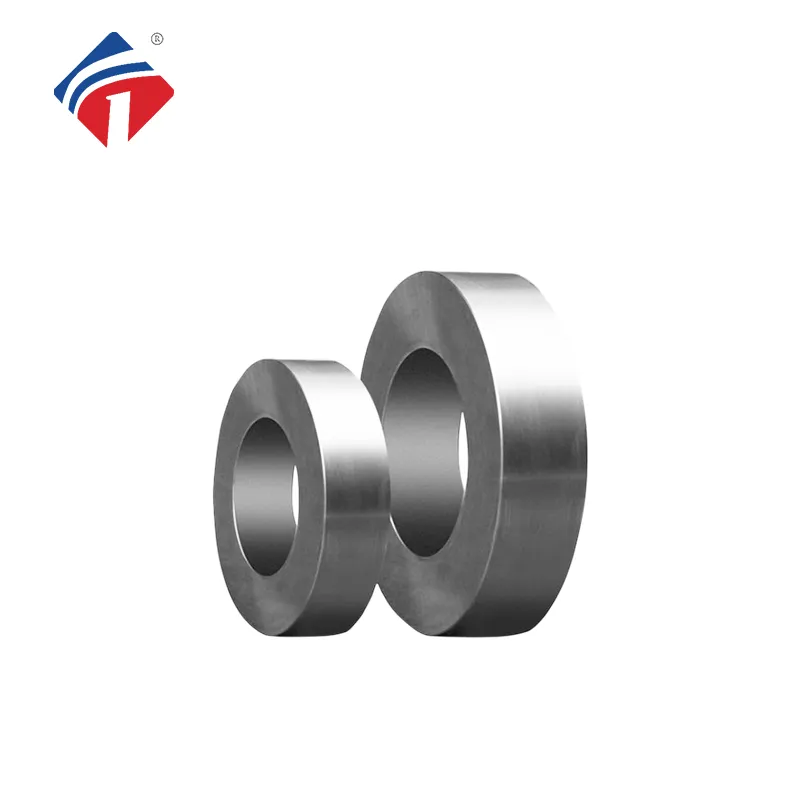

In the manufacturing of structural steel shapes, tyhightech’s roll rings for pilger mills provide the strength needed for heavy-duty rolling. These rings handle the intense forces of shaping beams and channels, ensuring precise dimensions and surface quality. Their durability makes them a staple in construction and infrastructure projects.

Choose tyhightech for roll rings that power structural steel production. Their advanced materials resist wear and deformation, ensuring consistent performance. With tyhightech, you get tools that combine precision and toughness, helping you build the future with confidence.

Smart manufacturing is changing the game, and tyhightech’s roll rings for pilger mills are part of it. Sensors embedded in rings to monitor wear and performance are gaining buzz, helping predict maintenance and avoid downtime. These smart tools keep production smooth and efficient. tyhightech is embracing this tech-forward trend, offering rings that blend brains with brawn. Step into the future of rolling with tools that think as hard as they work.

Eco-conscious manufacturing is easier than ever. tyhightech’s roll rings for pilger mills are made with recyclable carbide, supporting a circular economy. Their extended lifespan reduces the demand for new materials, making them a green choice for steel and wire production. Sustainability and strength go hand in hand with these innovative tools.

Built for tough rolling tasks, these rings resist wear and deliver consistent results. Their low maintenance needs save energy, while recycling options keep waste minimal. Choose these rings to align your operations with eco-friendly goals and enjoy reliable performance that lasts.

Smart spending starts with tyhightech’s roll rings for pilger mills. They cost more upfront but save big long-term with less upkeep and longer life. Value adds up fast.

With tyhightech, you invest wisely. Our roll rings blend performance and savings, proving their worth over time. Enjoy cost-effective quality that pays off.

Q: How do they handle abrasive materials?

A: The extreme hardness of the material resists scratching and abrasion, even when processing tough metals like stainless steel.

Q: Can these rings be used in cold rolling processes?

A: Absolutely, their strength and precision make them effective for cold rolling, where surface finish and accuracy are critical.

Q: What is the typical hardness level of these rings?

A: They often reach hardness levels above 85 HRA (Rockwell A scale), far exceeding many other materials used in similar applications.

Q: Why are they considered a premium choice for rolling mills?

A: Their combination of durability, precision, and resistance to extreme conditions justifies the investment, delivering unmatched performance and reliability.

The precision of these carbide rolls is outstanding. They consistently deliver accurate results, ensuring high-quality output for our products.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

Copyright © Tian Yi All Rights Reserved