Every operation is different, and tyhightech’s reduce downtime with carbide rolls for high-temperature applications rise to the challenge. Customizable to your specs, they fit your mill perfectly, boosting efficiency and output.

Tailor your success with tyhightech. Our reduce downtime with carbide rolls for high-temperature applications are made to match your needs, delivering precision and performance. Get exactly what you want.

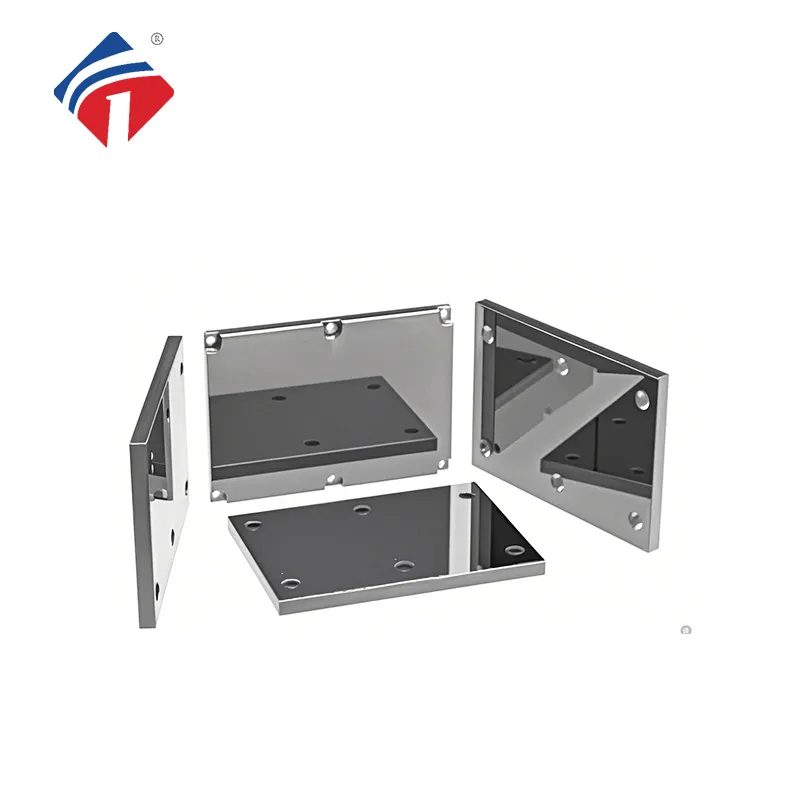

In the production of seamless tubes, tyhightech’s reduce downtime with carbide rolls for high-temperature applications are essential for achieving precision and durability. These rings withstand the intense forces of tube rolling, maintaining their shape and surface integrity under high temperatures. Used in industries like oil and gas, they ensure the production of flawless pipes with consistent wall thickness. Their resistance to thermal shock and abrasion makes them ideal for continuous, high-speed operations.

Elevate your tube manufacturing with tyhightech’s reliable roll rings. Designed for tough conditions, they minimize wear and extend operational life, reducing costly downtime. Their precision engineering ensures smooth surfaces and accurate dimensions, critical for high-performance tubing. Trust tyhightech to deliver tools that power your success in seamless tube production.

Customization is stealing the spotlight, and tyhightech’s reduce downtime with carbide rolls for high-temperature applications are leading the way. Tailored sizes and compositions are trending, letting manufacturers match rings to specific needs, from rebar to fine wires. This flexibility boosts efficiency and cuts costs. tyhightech makes it easy to get exactly what you need, no fuss. Dive into this trend for tools that fit your production like a glove.

Eco-conscious manufacturing is easier than ever. tyhightech’s reduce downtime with carbide rolls for high-temperature applications are made with recyclable carbide, supporting a circular economy. Their extended lifespan reduces the demand for new materials, making them a green choice for steel and wire production. Sustainability and strength go hand in hand with these innovative tools.

Built for tough rolling tasks, these rings resist wear and deliver consistent results. Their low maintenance needs save energy, while recycling options keep waste minimal. Choose these rings to align your operations with eco-friendly goals and enjoy reliable performance that lasts.

Smart spending starts with tyhightech’s reduce downtime with carbide rolls for high-temperature applications. They cost more upfront but save big long-term with less upkeep and longer life. Value adds up fast.

With tyhightech, you invest wisely. Our roll rings blend performance and savings, proving their worth over time. Enjoy cost-effective quality that pays off.

Q: Are they suitable for all rolling mills?

A: They work with most systems, though adjustments to cooling or lubrication might be needed for optimal integration.

Q: What’s the price range for these roll rings?

A: While they cost more initially than traditional materials, their longevity and reduced upkeep expenses often offset the investment.

Q: How do they contribute to long-term savings?

A: Their extended lifespan and minimal maintenance needs cut down on replacement frequency and operational interruptions, lowering overall costs.

Q: Do manufacturers provide warranties for them?

A: Most suppliers offer warranties covering material or manufacturing defects, though terms differ by provider.

These rolls perform exceptionally well under high-temperature conditions.

The precision of these carbide rolls is outstanding. They consistently deliver accurate results, ensuring high-quality output for our products.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved