Need flexibility? tyhightech’s how to select carbide roll rings for finishing stands adapt to various materials and conditions effortlessly. From steel to alloys, they perform consistently, making them a go-to for diverse production lines.

Choose tyhightech for adaptable solutions. Our how to select carbide roll rings for finishing stands bring versatility to your mill, ensuring quality across the board. Simplify your operations with this all-purpose performer.

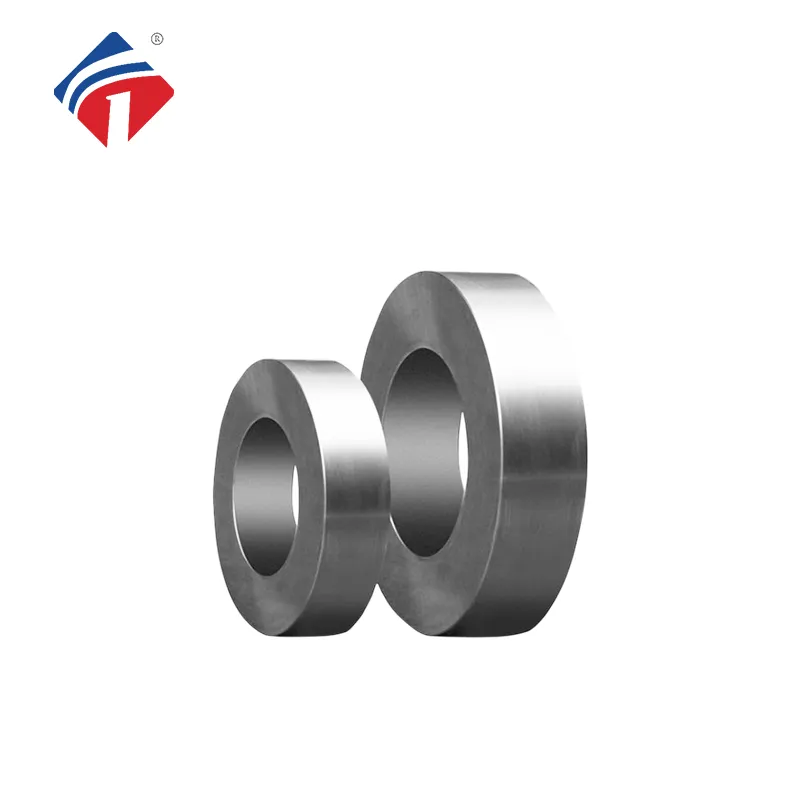

Cold rolling of stainless steel benefits from tyhightech’s how to select carbide roll rings for finishing stands, which offer precision and durability. These rings resist corrosion and wear, ensuring smooth, defect-free surfaces for high-value products like kitchenware and medical equipment. Their strength supports tight tolerances, critical for thin-gauge rolling.

Tyhightech’s roll rings elevate cold rolling with their superior craftsmanship. Designed for longevity, they reduce maintenance costs and enhance productivity. Their ability to maintain surface quality makes them ideal for premium stainless steel applications. Trust tyhightech for tools that deliver excellence in every roll.

High-speed rolling is hotter than ever, and tyhightech’s how to select carbide roll rings for finishing stands are built for the challenge. Enhanced thermal stability lets these rings handle blazing speeds without warping, perfect for high-output steel plants. Their tough design shrugs off wear, keeping lines moving. tyhightech delivers the speed and reliability you need to stay competitive. Get ready to roll faster and smarter with tools that keep up with the pace.

Make a difference with eco-smart rolling solutions. tyhightech’s how to select carbide roll rings for finishing stands are designed for longevity, reducing the need for frequent replacements and conserving resources. Made with recyclable carbide, they support a circular economy, letting you roll with confidence while staying green. It’s sustainability that doesn’t skimp on strength or precision.

These rings handle intense rolling tasks, from steel bars to fine wires, with minimal wear. Their robust build cuts down on maintenance, saving energy and costs. Recycling options make disposal easy and eco-friendly. Pick these rings to boost your production while keeping your environmental impact low and your results high.

Future-ready design defines tyhightech’s how to select carbide roll rings for finishing stands. Advanced materials prepare them for tomorrow’s demands. Stay ahead with forward-thinking components.

Invest in tyhightech for the long haul. Our roll rings adapt to evolving needs, keeping you competitive. Embrace what’s next with confidence.

Q: How are these components manufactured?

A: They are produced through a process of powder metallurgy, involving pressing and sintering to achieve a dense, durable structure.

Q: Do they require special maintenance?

A: Minimal upkeep is needed due to their inherent toughness, though regular inspection for wear ensures optimal performance.

Q: What happens if these rings wear out?

A: Worn rings can often be re-ground or refurbished, extending their usability before a full replacement is necessary.

Q: Are they environmentally friendly?

A: Their long service life reduces waste, and some manufacturers use recyclable materials in production, supporting sustainability efforts.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

The precision of these carbide rolls is outstanding. They consistently deliver accurate results, ensuring high-quality output for our products.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

Copyright © Tian Yi All Rights Reserved