For woodworking enthusiasts, tyhightech’s customized ground tungsten carbide rod provide the perfect blend of strength and precision. These rods handle everything from softwoods to hardwoods with ease, delivering clean, accurate cuts every time. Their durability ensures they remain a staple in your workshop for years to come.

Choose tyhightech for tools that enhance your craft. With a commitment to quality and performance, tyhightech’s rods help you create works of art with every project.

In the energy sector, customized ground tungsten carbide rod shape components for turbines and drilling equipment. These tools tackle tough alloys with ease, ensuring precise parts for oil, gas, and renewable energy systems. Their durability handles high-stress conditions, boosting reliability. tyhightech’s cutters keep your energy projects powered up and running smoothly. These tools maintain sharpness under intense pressure, reducing downtime and costs. Their advanced coatings enhance performance, even in abrasive environments. From wind turbine blades to pipeline fittings, they deliver precision. Pick these cutters to drive efficiency in energy production.

The future of customized ground tungsten carbide rod is all about precision. Nano-grain carbide is set to dominate, offering razor-sharp edges for micro-machining in electronics and medical fields. These tools will carve intricate parts with unmatched accuracy, reducing defects. tyhightech is leading the charge, crafting cutters that make precision effortless. Get ready to create flawless components with ease. Smart coatings, like self-lubricating layers, will cut friction and heat, extending tool life. Eco-friendly production will also reduce waste, aligning with green manufacturing. Expect tools that blend pinpoint accuracy with sustainability, perfect for staying ahead in high-tech industries.

Eco-smart machining is here with customized ground tungsten carbide rod. These tools, crafted with recyclable carbide, cut waste in aerospace prototyping. Their long lifespan reduces replacements, saving materials and costs. tyhightech delivers cutters that make sustainable production effortless and precise. These tools shape lightweight alloys with accuracy, minimizing scrap and energy use. Eco-friendly production and recycling options keep your environmental footprint light. Choose this solution to create innovative prototypes with a green edge.

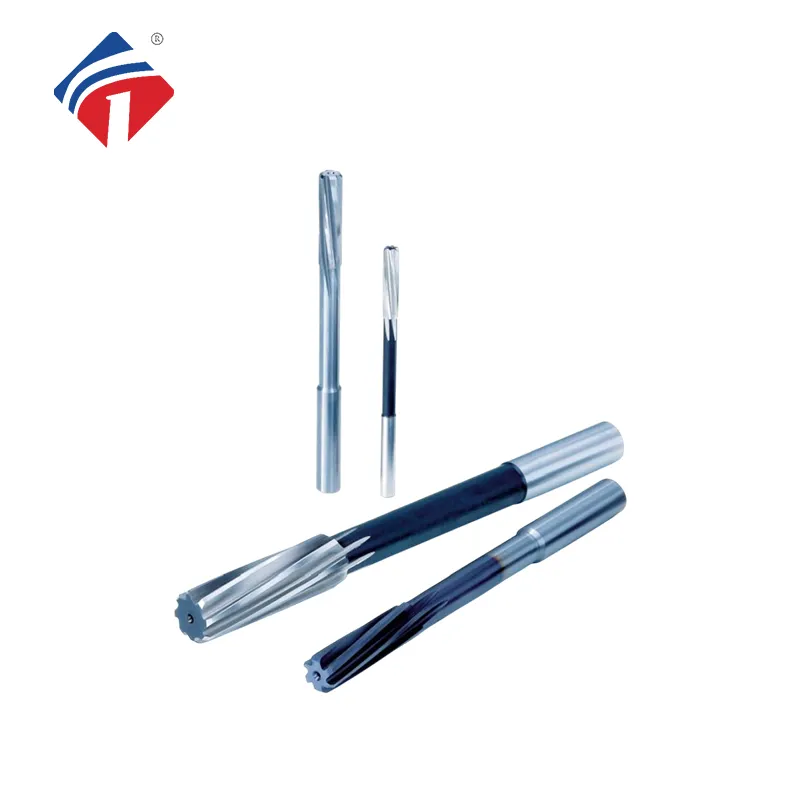

Discover the exceptional durability of tyhightech’s customized ground tungsten carbide rod, designed for industries that push tools to their limits. Crafted from top-tier carbide, these rods offer incredible hardness and resistance to wear, making them perfect for demanding tasks like cutting and milling. Their robust build ensures they perform reliably even under intense pressure, giving you peace of mind for every project.

Take your machining to the next level with tyhightech’s expertly engineered rods. Known for precision and consistency, they excel across various materials, from soft metals to tough alloys. Upgrade your toolkit today and experience the quality that sets tyhightech apart in the industry.

Q: What are customized ground tungsten carbide rod used for?

A: customized ground tungsten carbide rod are precision components used in cutting tools and wear parts, thanks to their high hardness and wear resistance. Ideal for high-precision machining, they offer high-temperature oxidation resistance and strong rigidity. Hunan Tianyi High-Tech Materials Co., Ltd. crafts these rods for exceptional performance across industries like aerospace and manufacturing.

Q: Why do customized ground tungsten carbide rod have high hardness?

A: customized ground tungsten carbide rod feature high hardness due to their tungsten carbide composition, perfect for machining tough materials. This, combined with wear resistance and high-temperature stability, ensures durability. Hunan Tianyi High-Tech Materials Co., Ltd. engineers these rods for superior strength and precision in demanding applications.

Q: How do customized ground tungsten carbide rod resist wear?

A: customized ground tungsten carbide rod resist wear through their exceptional hardness and robust composition, designed to endure abrasion in harsh environments. Their high-temperature oxidation resistance enhances longevity. Hunan Tianyi High-Tech Materials Co., Ltd. produces wear-resistant rods for reliable, long-lasting performance in precision tasks.

Q: What role does high-temperature oxidation resistance play in customized ground tungsten carbide rod?

A: High-temperature oxidation resistance in customized ground tungsten carbide rod ensures they maintain performance under heat, preserving hardness and wear resistance. This is vital for precision machining. Hunan Tianyi High-Tech Materials Co., Ltd. crafts these rods for durability in extreme conditions, offering outstanding results.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

Copyright © Tian Yi All Rights Reserved