Safety first—that’s the promise of tyhightech’s comparison of carbide roll rings and steel roll rings for stainless steel production. Their sturdy make lowers risks, keeping your team and equipment secure during every run.

Protect what matters with tyhightech. Our comparison of carbide roll rings and steel roll rings for stainless steel production prioritize reliability and safety, giving you confidence. Build a safer workplace now.

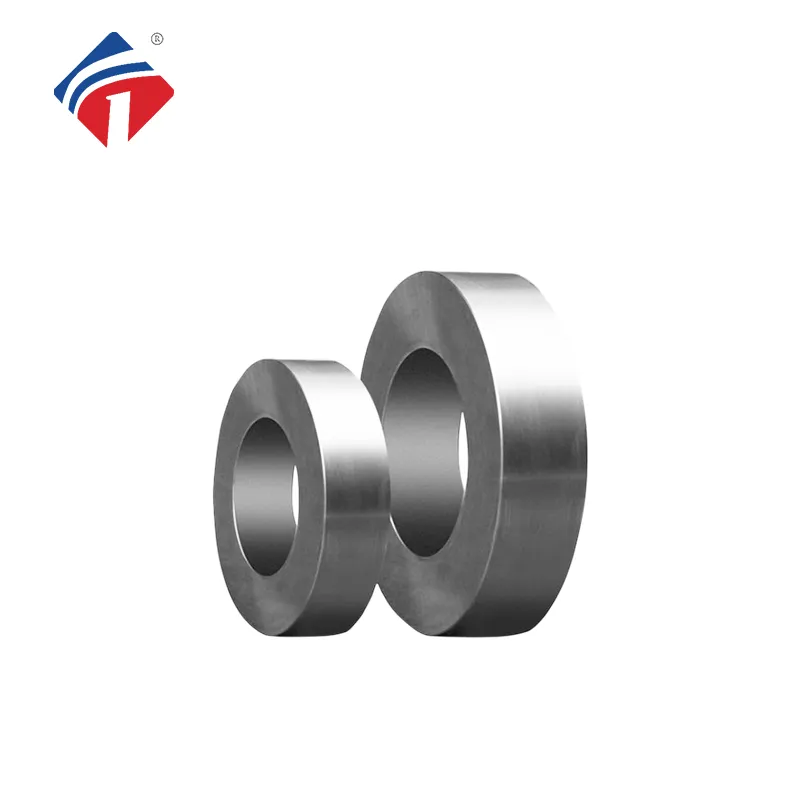

In steel rolling mills, tyhightech’s comparison of carbide roll rings and steel roll rings for stainless steel production shine as critical components for producing high-quality steel products. Their exceptional hardness and wear resistance allow them to withstand the intense pressure and friction of hot and cold rolling processes. These rings maintain precise dimensions, ensuring consistent output for steel bars, sheets, and wires. Used in high-speed rolling operations, they reduce downtime by resisting cracking and deformation, even under extreme conditions. tyhightech delivers reliability that keeps production lines running smoothly, making these rings a top choice for steel manufacturers worldwide.

Boost your steel production with tyhightech’s expertly crafted roll rings. Designed for durability, they handle the toughest alloys, delivering flawless finishes and minimizing maintenance costs. Their thermal stability ensures performance in high-heat environments, while their robust construction extends service life. From structural beams to fine wires, tyhightech’s rings provide the precision and strength needed to excel in demanding steel rolling applications.

Durability is always in style, and tyhightech’s comparison of carbide roll rings and steel roll rings for stainless steel production are tougher than ever. New alloy blends are trending, boosting resistance to cracks and wear in high-stress rolling. These rings keep going strong, even in brutal conditions like hot rolling. tyhightech delivers long-lasting performance that saves you money. Ride this durability wave for tools that stand the test of time.

Make sustainability simple with top-tier rolling tools. tyhightech’s comparison of carbide roll rings and steel roll rings for stainless steel production use recyclable materials and efficient production methods, reducing environmental impact. Their durability minimizes replacements, saving resources and cutting costs. It’s an easy way to green your operations without losing performance.

These rings handle everything from steel sheets to fine wires with precision and strength. Their low maintenance and recyclability make them a smart choice for eco-conscious manufacturers. Roll with confidence, knowing you’re choosing tools that prioritize both quality and the planet.

Ease of use cuts downtime, and tyhightech’s comparison of carbide roll rings and steel roll rings for stainless steel production fit right in. Designed to work with many mills, they install quickly and smoothly. Compatibility keeps your operations on track.

tyhightech focuses on keeping you moving. Our roll rings are crafted for a flawless fit, boosting your system effortlessly. Upgrade with confidence using components that simplify the process.

Q: Can these rings withstand heavy mechanical stress?

A: Yes, their high compressive strength allows them to endure significant force without cracking or deforming, ensuring reliability in tough environments.

Q: How long do these roll rings typically last?

A: Thanks to their wear-resistant properties, they often outlast traditional steel alternatives by several times, reducing replacement frequency.

Q: Are they resistant to corrosion?

A: The material composition provides excellent resistance to rust and chemical degradation, enhancing longevity in humid or acidic conditions.

Q: What makes these rings different from steel versions?

A: They offer greater hardness and thermal stability, resulting in less wear and better performance compared to conventional steel options.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

These cemented carbide rolls are incredibly durable and have significantly improved our production efficiency.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

Do you offer customized cemented carbide rolls? We require specific dimensions and coatings for our ...

Copyright © Tian Yi All Rights Reserved