Go green with tyhightech’s comparison of carbide roll rings and steel roll rings for continuous rolling mills, designed for eco-friendly manufacturing. Their longevity cuts down on waste, and their efficient operation reduces energy use. Sustainability and strength go hand in hand here.

Opt for tyhightech and make a difference. Our comparison of carbide roll rings and steel roll rings for continuous rolling mills support your environmental goals while delivering top-notch results. Embrace a cleaner, more efficient future today.

In the manufacturing of structural steel shapes, tyhightech’s comparison of carbide roll rings and steel roll rings for continuous rolling mills provide the strength needed for heavy-duty rolling. These rings handle the intense forces of shaping beams and channels, ensuring precise dimensions and surface quality. Their durability makes them a staple in construction and infrastructure projects.

Choose tyhightech for roll rings that power structural steel production. Their advanced materials resist wear and deformation, ensuring consistent performance. With tyhightech, you get tools that combine precision and toughness, helping you build the future with confidence.

Compact designs are making waves, and tyhightech’s comparison of carbide roll rings and steel roll rings for continuous rolling mills are leading the charge. Smaller, lighter rings are trending for precision applications like electronics, where space is tight. They still pack the same strength and precision, just in a sleeker package. tyhightech nails this balance, offering compact tools that don’t skimp on power. Join the trend for efficient, space-saving rolling solutions.

Sustainability meets strength in rolling technology. comparison of carbide roll rings and steel roll rings for continuous rolling mills from tyhightech use eco-conscious production methods, reducing carbon footprints while delivering top performance. Their exceptional durability extends service life, cutting down on raw material use and waste. It’s a smart choice for manufacturers who want to balance quality with environmental responsibility.

These rings are built to last, handling tough tasks like hot rolling with ease. By reducing replacements, they save energy and resources, making your operations leaner and greener. Their precision ensures consistent output, minimizing scrap. Choose these sustainable tools to roll out a brighter, eco-friendly future for your industry.

Support doesn’t stop at purchase with tyhightech. Our comparison of carbide roll rings and steel roll rings for continuous rolling mills come with full after-sales care, from setup help to ongoing advice. We’ve got your back.

Choose tyhightech for lasting teamwork. Our roll rings ensure smooth running with expert assistance always available. Rest easy knowing help is near.

Q: What upkeep do they require?

A: Regular maintenance involves ensuring effective cooling and lubrication to avoid overheating, along with periodic checks for wear or damage.

Q: Do they come in various sizes?

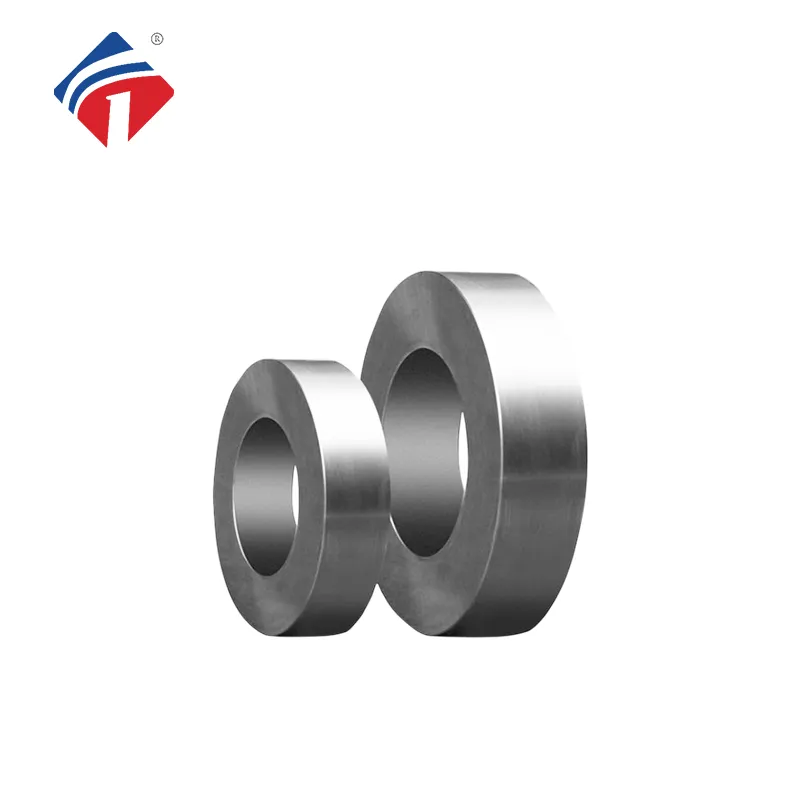

A: Indeed, they are available in a range of dimensions, with outer diameters up to 550 millimeters, to suit different rolling mill setups.

Q: Can they be tailored for specific needs?

A: Yes, customization options include unique groove patterns and sizes to match particular rolling applications, enhancing performance.

Q: How should one select the appropriate roll ring?

A: Consider the type of metal, rolling speed, and desired output finish. Consulting a specialist can help pinpoint the best option.

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Could you please provide detailed information about your cemented carbide rolls, including specifica...

Copyright © Tian Yi All Rights Reserved