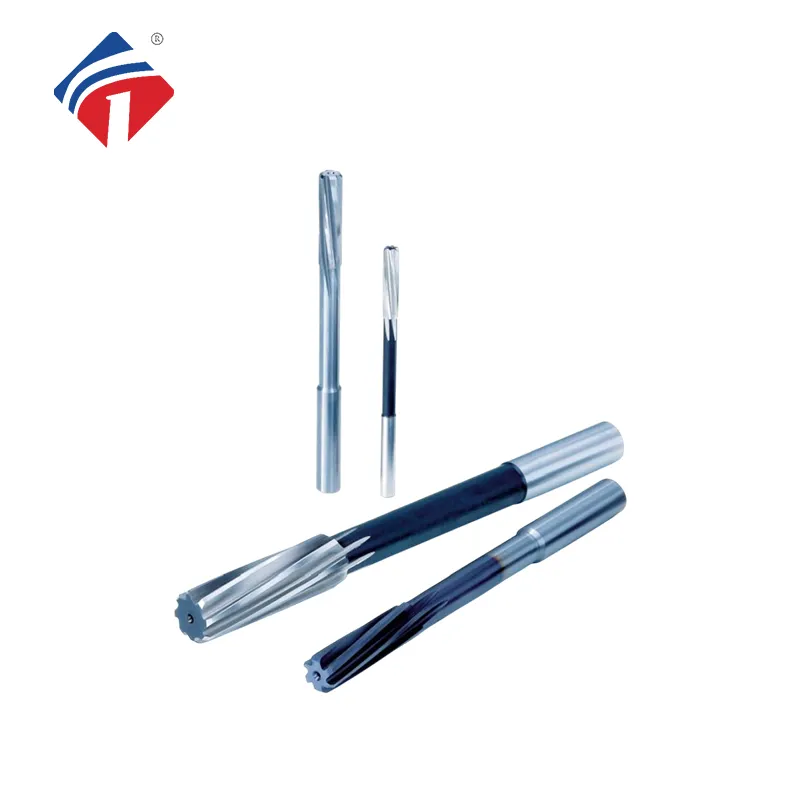

Craft complex shapes easily with tyhightech’s tapered CNC End Mills For Lathe. Their angled design excels in mold work and angled cuts, bringing precision to intricate details.

Made from top-grade carbide, tyhightech’s tapered tools resist wear with special coatings. Create stunning designs with the accuracy and strength these end mills provide.

Picture this: a tool that effortlessly tackles tough materials, turning ideas into reality. That's the magic of CNC End Mills For Lathe, ideal for a host of applications that demand precision and speed. In the automotive sector, they sculpt engine blocks with unmatched detail, while aerospace pros rely on them for lightweight alloy parts. Woodworkers love how they create ornate patterns on cabinets, and jewelers use them for delicate engravings. Even in PCB fabrication, these cutters ensure circuit integrity. Tyhightech steps in with quality selections that promise durability and ease. For mold making in injection processes, they're indispensable for fine features. Why settle for less when you can achieve pro-level outcomes? Embrace these game-changers for projects that wow every time—efficiency and excellence rolled into one!

Get ready for a thrilling ride in machining innovation as CNC End Mills For Lathe step into the spotlight of 2025 and beyond. Picture cutters enhanced by machine learning, optimizing paths for flawless finishes in record time. New materials like nano-carbides promise durability against the toughest alloys, while smart sensors embedded in tools monitor performance in real-time. Hybrid manufacturing merges 3D printing with milling for rapid prototyping that's both precise and versatile. Tyhightech offers reliable options that align with these trends, enhancing your workflow without hassle. Digital integration connects everything via IoT, streamlining from design to delivery. For industries like automotive and electronics, this means faster innovation and less error. It's convincing: adopting these forward-thinking tools elevates efficiency and sparks creativity. Dive in now—your future-proof setup awaits with open arms!

Sustainability is easy with Cemented Carbide’s long-lasting performance. These tools, made with recyclable carbide, reduce the need for frequent replacements, conserving materials. tyhightech’s designs support a circular economy, making your production greener. It’s a smart choice for manufacturers who want quality and eco-responsibility in one package.

From cutting tools to wear parts, these solutions handle high-stress jobs while minimizing waste. Low-energy manufacturing and recyclable binders keep the environmental impact low. Pick this path to roll out sustainable, high-performance products that impress.

Picture tyhightech’s CNC End Mills For Lathe as your machining multitaskers—ready for anything. They tackle roughing, finishing, and everything in between, adapting to diverse materials with ease and reliability.

With tyhightech, you’re choosing streamlined workflows and consistent outcomes. These end mills cut setup time and boost efficiency, proving quality engineering transforms your shop’s potential.

Q: What edge do carbide tools have over HSS?

A: Carbide cuts faster and lasts longer, especially on tough materials like titanium, thanks to its hardness and heat resistance. HSS, while cheaper and more flexible, wears quicker, making carbide ideal for heavy-duty use.

Q: Is resharpening an option for these tools?

A: Yes, particularly for carbide, resharpening extends life if done precisely to preserve geometry. It’s cost-effective for larger tools, though smaller or worn-out ones might be better replaced.

Q: What safety steps should I follow?

A: Wear safety gear like glasses and gloves, secure the tool and machine, and use correct speeds to avoid breakage. Keep the workspace clear of chips and debris to reduce risks.

Q: Where can I source reliable cutting tools?

A: Seek trusted suppliers with industry credibility, diverse options, and solid support. Look for detailed product specs and customer feedback to ensure you get tools suited to your needs.

These cemented carbide rolls are incredibly durable and have significantly improved our production efficiency.

Although the initial cost is higher, the long lifespan and reduced replacement frequency make these rolls a cost-effective solution.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide detailed information about your cemented carbide rolls, including specifica...

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

Copyright © Tian Yi All Rights Reserved