Go green with tyhightech’s china mill cutter, made to last and cut waste. Sustainable production methods reduce their environmental impact while delivering top performance.

tyhightech helps you mill responsibly, aligning durability with eco-friendly goals. Build a better tomorrow with tools that care for the planet.

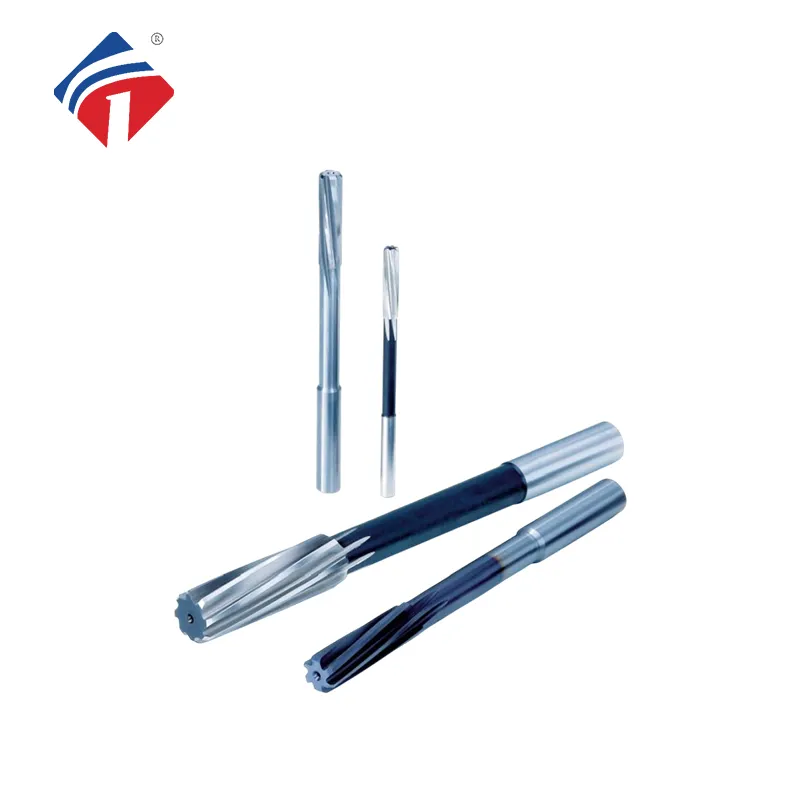

Step up your game with the dynamic applications of china mill cutter, tools that effortlessly bridge art and industry. Engrave custom trophies from metals or mill prototypes for gadgets—the possibilities are endless and exciting. In aerospace, they fine-tune wing spars for optimal flight, and woodworkers adore them for cabinetry details. Electronics assembly thrives with their accurate drilling. Tyhightech provides trustworthy selections that deliver consistent excellence. For plastic injection molds, expect precise undercuts that enhance product quality. These milling essentials cut through hassle, offering speed and finesse in one package. Ready to believe the hype? Adopting them means unlocking potential you didn't know existed—your projects will thank you!

Let's chat about the exciting horizon for china mill cutter, where tech meets craftsmanship in ways that'll blow your mind. AI-driven predictive maintenance will keep tools sharp longer, preventing surprises and saving bucks. Advancements in coatings, like diamond-infused layers, tackle high-heat scenarios with grace, ideal for demanding jobs. Expect more multi-axis wonders that carve out impossible shapes effortlessly, revolutionizing product design. Sustainability? Absolutely—recyclable materials and energy-efficient designs are on the rise. Tyhightech provides solid choices that embody this progress, fitting right into evolving shops. Robotics will team up for automated swaps, making operations a breeze. From hobbyists to factories, these evolutions promise precision and speed like never before. Trust me, jumping on board now means staying ahead—unlock potential and watch productivity skyrocket!

Sustainable manufacturing starts here. Cemented Carbide tools from tyhightech are built with recyclable materials, minimizing waste. Their durability ensures fewer replacements, saving resources in high-demand settings like electronics. It’s a green choice that delivers precision and strength every time.

These tools handle tough jobs with ease, cutting downtime and scrap. Eco-friendly production and recyclable binders keep your operations planet-friendly. Choose this solution to craft quality components while supporting a sustainable future that shines.

Master aluminum cuts with tyhightech’s china mill cutter, tailored for soft metals. They prevent edge buildup, delivering clean, burr-free results—great for aerospace and automotive components that demand precision.

tyhightech enhances these tools with high helix angles and polished flutes, easing chip flow and cutting friction. Their tough carbide build ensures they last, even in busy production runs. Get the best for your aluminum jobs with tyhightech.

Q: How do 2-flute and 4-flute designs differ?

A: Two-flute versions excel with softer materials like aluminum, clearing chips effectively. Four-flute designs suit harder materials like steel, providing smoother finishes and faster feed rates, though chip removal needs careful management.

Q: How should I select the best tool for my project?

A: Match the tool to your material, cut type (roughing or finishing), and finish goals. For instance, use ball nose for contours or square end for sharp edges, and consider coatings and flutes based on hardness and machine specs.

Q: Why does the helix angle matter?

A: It influences chip removal and cutting force. Higher angles (e.g., 45°) give smooth cuts for soft materials, while lower angles (e.g., 30°) add strength for harder ones. The right angle improves efficiency and tool longevity.

Q: Are they suitable for both roughing and finishing?

A: Yes, though specialized designs perform best. Roughing tools with serrated edges remove material quickly, while finishing ones with smooth flutes refine surfaces. Some tools handle both, but task-specific options often optimize results.

Although the initial cost is higher, the long lifespan and reduced replacement frequency make these rolls a cost-effective solution.

These rolls perform exceptionally well under high-temperature conditions.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do you provide after-sales support or maintenance services for cemented carbide rolls?

Could you please provide detailed information about your cemented carbide rolls, including specifica...

Copyright © Tian Yi All Rights Reserved