Rely on tyhightech’s square end china cnc rough end mill factory for solid slotting and profiling. Their flat tips and crisp corners carve exact pockets and edges in steel, plastics, and more.

tyhightech reinforces these workhorses with sturdy shanks and smart flute layouts for chip flow. From prototypes to full runs, they’re your go-to for dependable milling.

Curious about what makes machining tick? china cnc rough end mill factory lead the charge in diverse scenarios, from contouring aircraft fuselages to slotting keys in locks. They're stars in jewelry for intricate filigree work and in electronics for board prototyping. Automotive fans use them for brake caliper mods, ensuring safety and style. Tyhightech brings solid options to the table, fitting right into your arsenal. In woodworking, they craft dovetail joints flawlessly, while mold makers rely on them for cavity precision. These cutters aren't mere accessories—they're efficiency boosters that save time and spark innovation. Why not give your setup a refresh? With their help, expect standout performance and results that impress clients and peers alike!

Imagine a future where china cnc rough end mill factory aren't just cutters—they're intelligent allies in your workshop. By 2025, AI integration will enable self-adjusting feeds, ensuring optimal cuts every time. Innovative alloys and hybrid tech will handle exotic materials with pinpoint accuracy, pushing boundaries in aerospace and beyond. Digital twins simulate performance virtually, cutting trial-and-error drastically. Eco-conscious features, like biodegradable lubricants, align with green manufacturing goals. Tyhightech steps up with dependable variants that capture these innovations seamlessly. Multi-robot systems will orchestrate complex tasks, amplifying output without extra effort. It's all about efficiency and excellence, making high-end machining accessible. Convincing, right? Embrace this wave for tools that evolve with you, delivering results that impress and endure. The tomorrow of milling is here—make it yours!

Sustainable manufacturing starts here. Cemented Carbide tools from tyhightech are built with recyclable materials, minimizing waste. Their durability ensures fewer replacements, saving resources in high-demand settings like electronics. It’s a green choice that delivers precision and strength every time.

These tools handle tough jobs with ease, cutting downtime and scrap. Eco-friendly production and recyclable binders keep your operations planet-friendly. Choose this solution to craft quality components while supporting a sustainable future that shines.

Speed up your workflow with tyhightech’s high-speed china cnc rough end mill factory, built for rapid cutting without losing precision. These tools shine in fast-paced production lines, saving time while maintaining top-notch quality—perfect when deadlines loom large.

Innovation drives tyhightech’s high-speed lineup, with flute designs that cut vibration and premium materials that endure. Slash cycle times and keep your output sharp with milling tools engineered for peak performance.

Q: What’s the difference between upcut and downcut styles?

A: Upcut pulls chips up, aiding deep cuts but possibly roughing the top surface. Downcut pushes chips down for cleaner tops, though chip buildup needs monitoring. Choose based on finish priorities and material.

Q: How does flute count affect cutting?

A: More flutes speed up feeds and smooth finishes but demand higher spindle speeds and good chip clearance. Fewer flutes suit softer materials or deeper cuts. Balance this with your setup for best outcomes.

Q: Why is cutting diameter important?

A: It dictates cut width and tool strength. Smaller diameters detail fine work, while larger ones tackle heavy removal. The right size ensures accuracy and prevents breakage in precision tasks.

Q: How can I make these tools last longer?

A: Use proper speeds, feeds, and cooling, and avoid overcutting. Regular wear checks and resharpening help, as does storing them cleanly and dryly to maintain edge quality.

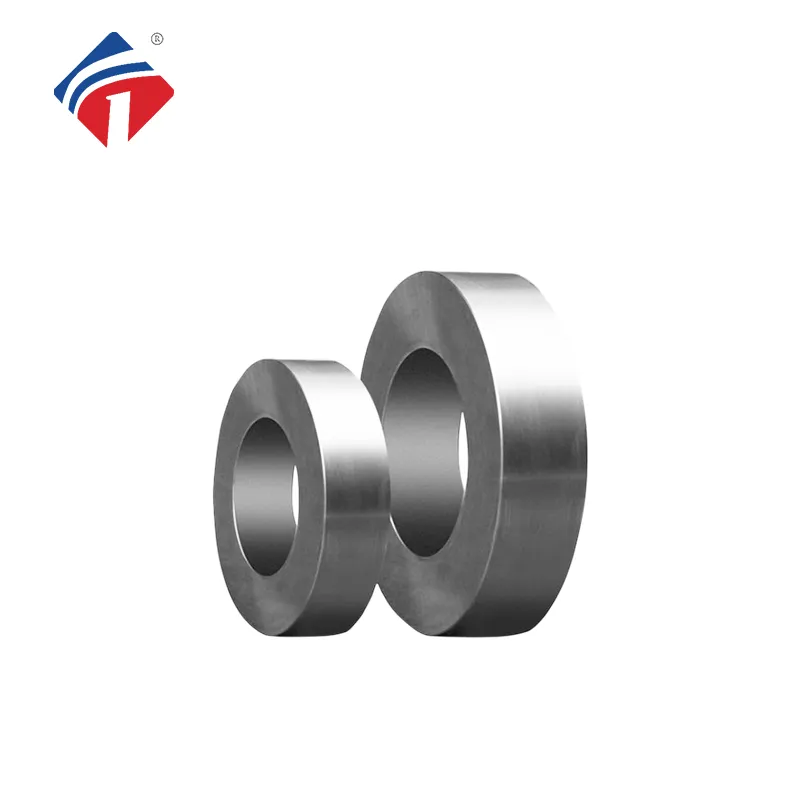

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

Copyright © Tian Yi All Rights Reserved