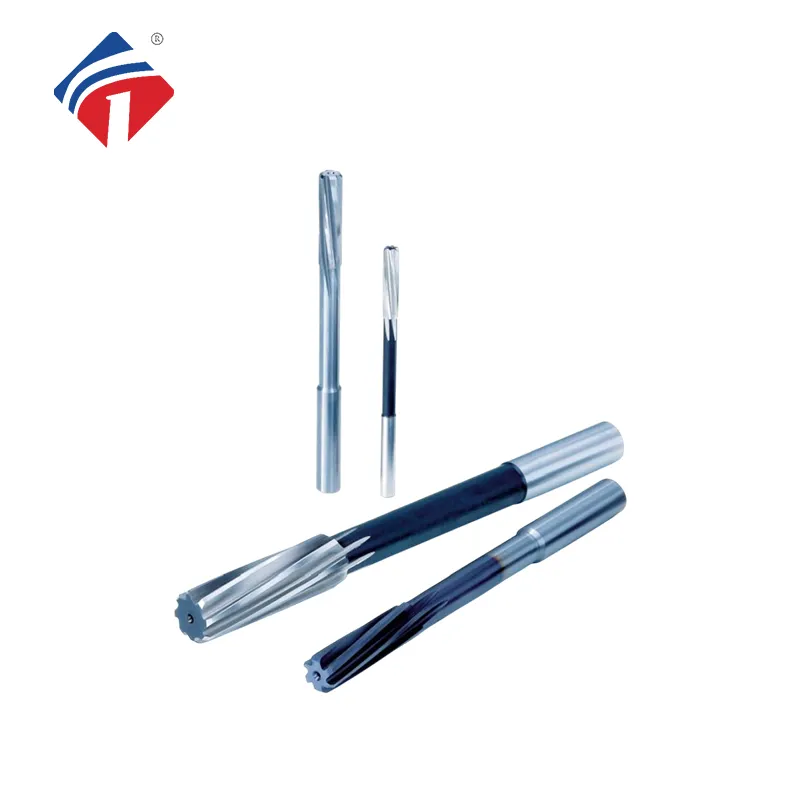

Cut smoother with tyhightech’s variable helix china carbide mill bits, designed to quiet vibration. Their unique angles tackle tough materials like titanium with ease and finesse.

tyhightech’s variable helix tools boost chip flow and reduce deflection, extending life and enhancing finishes. Push your milling limits with this next-level choice.

Get excited about the broad reach of china carbide mill bits, where they turn ordinary materials into extraordinary pieces. Slot milling for mechanical assemblies or contouring for artistic installations—they handle it with ease. Aerospace applications include airfoil shaping, and in woodworking, they create elegant moldings. Electronics pros mill enclosures precisely. Tyhightech supplies quality tools that fit perfectly into workflows. For injection molding dies, their accuracy prevents defects, saving big on revisions. These versatile cutters promote creativity while slashing waste, making them a smart pick for any setup. Trust us: incorporating them leads to smoother operations and impressive outcomes that build your reputation effortlessly!

Imagine a future where china carbide mill bits aren't just cutters—they're intelligent allies in your workshop. By 2025, AI integration will enable self-adjusting feeds, ensuring optimal cuts every time. Innovative alloys and hybrid tech will handle exotic materials with pinpoint accuracy, pushing boundaries in aerospace and beyond. Digital twins simulate performance virtually, cutting trial-and-error drastically. Eco-conscious features, like biodegradable lubricants, align with green manufacturing goals. Tyhightech steps up with dependable variants that capture these innovations seamlessly. Multi-robot systems will orchestrate complex tasks, amplifying output without extra effort. It's all about efficiency and excellence, making high-end machining accessible. Convincing, right? Embrace this wave for tools that evolve with you, delivering results that impress and endure. The tomorrow of milling is here—make it yours!

Go green without compromising strength! Cemented Carbide tools from tyhightech are crafted with recyclable materials, slashing waste in industries like mining and machining. Their durability means fewer replacements, saving resources and keeping production eco-friendly. It’s a simple way to make your workshop sustainable while delivering top-notch results every time.

These tools shine in tough tasks, resisting wear to extend service life. Eco-conscious production cuts emissions, and recycling programs make disposal a breeze. Choose this solution to keep your operations lean, green, and efficient, all while crafting high-quality components with ease.

Shape intricate designs effortlessly with tyhightech’s ball nose china carbide mill bits. Their rounded tips carve smooth, precise contours in molds and complex parts, making them a favorite in aerospace and medical fields where detail is everything.

Reliability comes standard with tyhightech. These ball nose tools feature fine carbide builds and friction-reducing coatings, offering exceptional finishes and extended durability. Choose tyhightech to bring your detailed projects to life with confidence and finesse.

Q: How do 2-flute and 4-flute designs differ?

A: Two-flute versions excel with softer materials like aluminum, clearing chips effectively. Four-flute designs suit harder materials like steel, providing smoother finishes and faster feed rates, though chip removal needs careful management.

Q: How should I select the best tool for my project?

A: Match the tool to your material, cut type (roughing or finishing), and finish goals. For instance, use ball nose for contours or square end for sharp edges, and consider coatings and flutes based on hardness and machine specs.

Q: Why does the helix angle matter?

A: It influences chip removal and cutting force. Higher angles (e.g., 45°) give smooth cuts for soft materials, while lower angles (e.g., 30°) add strength for harder ones. The right angle improves efficiency and tool longevity.

Q: Are they suitable for both roughing and finishing?

A: Yes, though specialized designs perform best. Roughing tools with serrated edges remove material quickly, while finishing ones with smooth flutes refine surfaces. Some tools handle both, but task-specific options often optimize results.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

Although the initial cost is higher, the long lifespan and reduced replacement frequency make these rolls a cost-effective solution.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

Copyright © Tian Yi All Rights Reserved