In the oil and gas industry, tools must withstand extreme conditions. tyhightech’s cemented alloy bar blanks are built to endure, providing the strength and durability needed for drilling and extraction. Their resilience ensures they perform reliably, even in the harshest environments.

Trust tyhightech for tools that can handle the toughest jobs. With a focus on quality and performance, tyhightech’s rods are the backbone of the oil and gas industry.

In the energy sector, cemented alloy bar blanks shape components for turbines and drilling equipment. These tools tackle tough alloys with ease, ensuring precise parts for oil, gas, and renewable energy systems. Their durability handles high-stress conditions, boosting reliability. tyhightech’s cutters keep your energy projects powered up and running smoothly. These tools maintain sharpness under intense pressure, reducing downtime and costs. Their advanced coatings enhance performance, even in abrasive environments. From wind turbine blades to pipeline fittings, they deliver precision. Pick these cutters to drive efficiency in energy production.

cemented alloy bar blanks are headed for a precision revolution. Ultra-fine grains and advanced coatings will deliver razor-sharp accuracy for micro-machining in medical devices. These tools will craft tiny components with zero defects. tyhightech’s cutters make precision effortless, turning ideas into reality. Your projects just got sharper. Eco-friendly production and recyclable materials will keep these tools green. Expect longer lifespans and less waste, saving resources while maintaining quality. The future’s bright for cutters that blend pinpoint accuracy with sustainability, perfect for high-tech industries.

Go green with cutting tools that last! cemented alloy bar blanks crafted with recyclable carbide reduce waste in industries like aerospace. Their durability means fewer replacements, saving resources and keeping your shop eco-friendly. tyhightech’s cutters make sustainability simple, delivering top performance with every precise cut. These tools resist wear, cutting down on maintenance and energy use. Eco-conscious production methods lower emissions, and recycling programs make disposal a breeze. Choose these cutters to create high-quality parts while supporting a greener future—sustainability never looked so sharp.

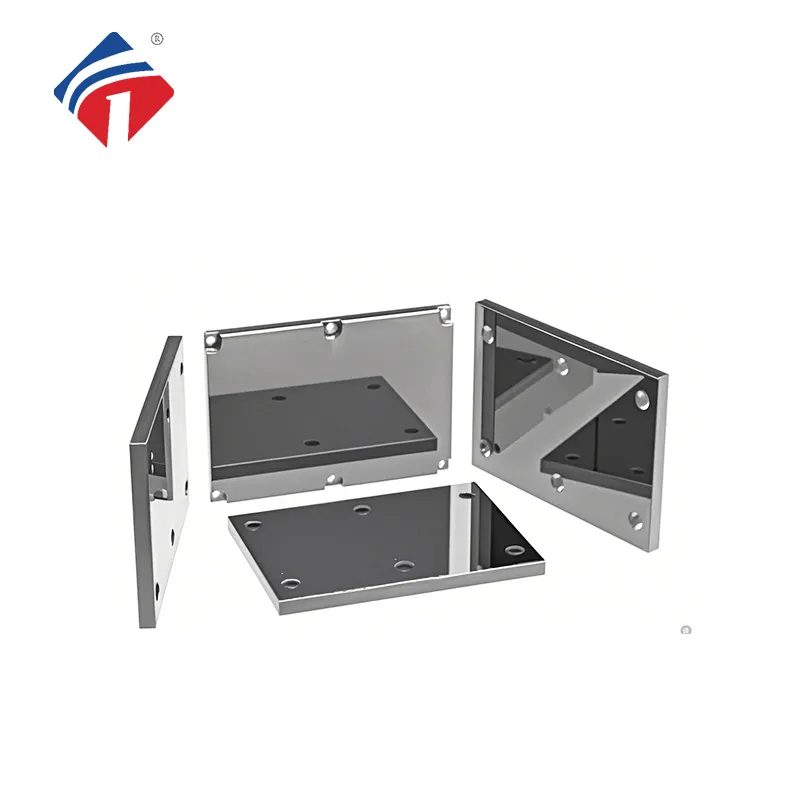

Customization is key with tyhightech’s cemented alloy bar blanks, offering tailored solutions to meet your specific needs. Whether you require unique dimensions or specialized compositions, tyhightech can deliver. Their flexibility ensures you get exactly what you need for your projects.

Experience the benefits of personalized tools with tyhightech. Their expert team works closely with you to create rods that perfectly match your requirements, enhancing your productivity and results.

Q: Can cemented alloy bar blanks machine multiple materials?

A: Yes, cemented alloy bar blanks handle multiple materials like steel, titanium, and composites with high hardness and wear resistance. Their strong rigidity and precision enable versatile, high-precision machining. Hunan Tianyi High-Tech Materials Co., Ltd. designs these rods for adaptable, top-tier performance across applications.

Q: How do cemented alloy bar blanks ensure high-precision machining?

A: cemented alloy bar blanks ensure high-precision machining with their ultra-high hardness, strong rigidity, and excellent surface finish. Their wear resistance and stability maintain accuracy during complex cuts. Hunan Tianyi High-Tech Materials Co., Ltd. engineers these rods for flawless, reliable precision in every project.

Q: What makes cemented alloy bar blanks rigid and strong?

A: cemented alloy bar blanks feature high rigidity and strength due to their robust tungsten carbide composition, combined with wear resistance and high-temperature stability. This ensures durability for precision applications. Hunan Tianyi High-Tech Materials Co., Ltd. crafts these rods for unyielding performance in tough tasks.

Q: How do cemented alloy bar blanks resist corrosion?

A: cemented alloy bar blanks resist corrosion through their strong composition and advanced manufacturing, maintaining high hardness and wear resistance in harsh environments. Their durability enhances longevity. Hunan Tianyi High-Tech Materials Co., Ltd. produces corrosion-resistant rods for reliable precision machining.

These cemented carbide rolls are incredibly durable and have significantly improved our production efficiency.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are looking for cemented carbide rolls for our steel processing plant. Could you share the techni...

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved