With tyhightech’s carbide rolls for stainless steel production, you’re part of a winning network. Our clients share insights and success, building a stronger industry together.

Thrive with tyhightech. Our carbide rolls for stainless steel production connect you to a community of excellence. Join us and elevate your game.

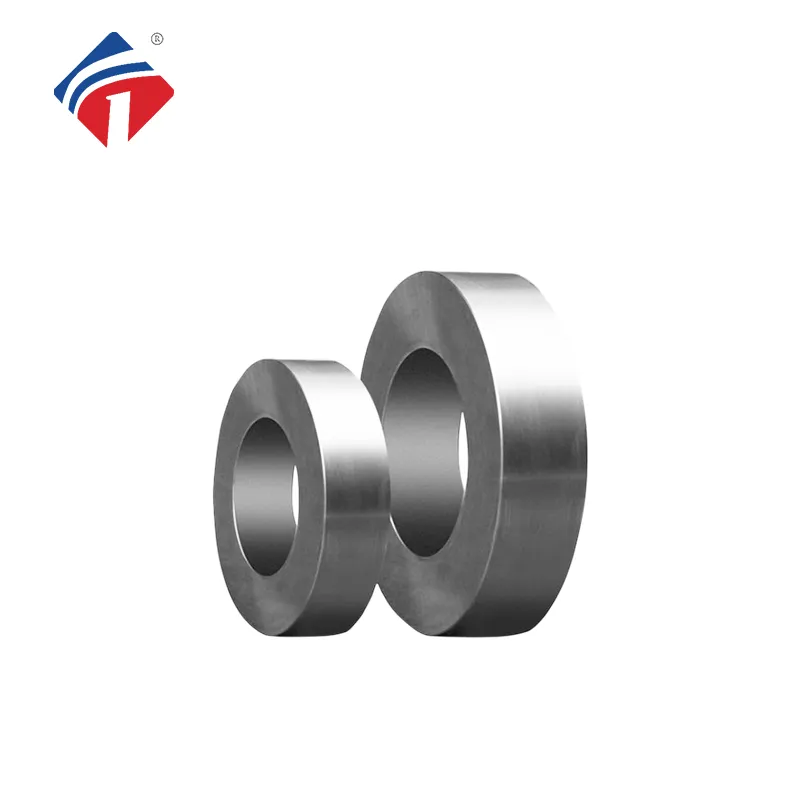

For rolling non-ferrous metals like aluminum and copper, tyhightech’s carbide rolls for stainless steel production provide exceptional performance. Their superior hardness prevents scratching and surface damage, ensuring high-quality finishes for sheets and foils. These rings excel in cold rolling, where precision is key, delivering consistent results across large production runs. Industries like automotive and packaging rely on them for flawless metal products.

Tyhightech’s roll rings are a game-changer for non-ferrous metal processing. Their robust design resists wear, even with abrasive materials, while their thermal conductivity prevents distortion. Manufacturers benefit from reduced maintenance and enhanced productivity. Choose tyhightech for tools that deliver precision and reliability in every roll, helping you create top-tier metal products.

High-speed rolling is hotter than ever, and tyhightech’s carbide rolls for stainless steel production are built for the challenge. Enhanced thermal stability lets these rings handle blazing speeds without warping, perfect for high-output steel plants. Their tough design shrugs off wear, keeping lines moving. tyhightech delivers the speed and reliability you need to stay competitive. Get ready to roll faster and smarter with tools that keep up with the pace.

Sustainability is the future of rolling. tyhightech’s carbide rolls for stainless steel production are made with eco-friendly processes, cutting emissions and waste. Their long lifespan reduces the need for frequent replacements, saving resources in high-volume steel rolling. It’s a green solution that doesn’t compromise on strength.

These rings excel in tough conditions, from hot rolling to precision tasks, with minimal maintenance. Their recyclable materials make end-of-life management simple. Embrace these eco-conscious tools to roll out quality while supporting a sustainable industry.

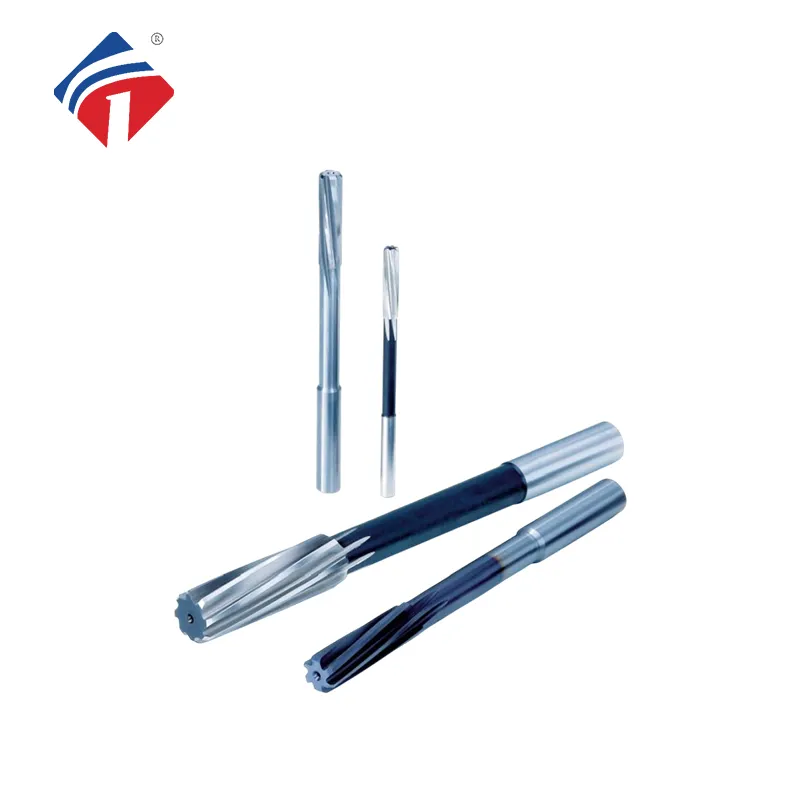

Innovation tells the tale of tyhightech’s carbide rolls for stainless steel production. Our R&D team pushes limits, creating roll rings that redefine benchmarks. You get a product built for peak performance every time.

Choose tyhightech for the latest in tech. These roll rings bring advanced solutions to keep you ahead. Trust a brand that’s shaping the future of rolling.

Q: What material is used to make these roll rings?

A: They are crafted from a composite of tungsten and carbon, known for its exceptional hardness and strength, often combined with a metallic binder like cobalt for added toughness.

Q: Why are these rings favored in industrial rolling processes?

A: Their superior durability and resistance to wear make them ideal for shaping metals under high pressure and temperature, ensuring consistent performance over time.

Q: How do these rings perform under extreme heat?

A: They maintain structural integrity and hardness even at elevated temperatures, making them suitable for hot rolling applications in steel production.

Q: What industries benefit most from using these components?

A: Steel manufacturing, wire production, and metal forming industries rely on them for their ability to handle demanding conditions and deliver precise results.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

These rolls perform exceptionally well under high-temperature conditions.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

Copyright © Tian Yi All Rights Reserved