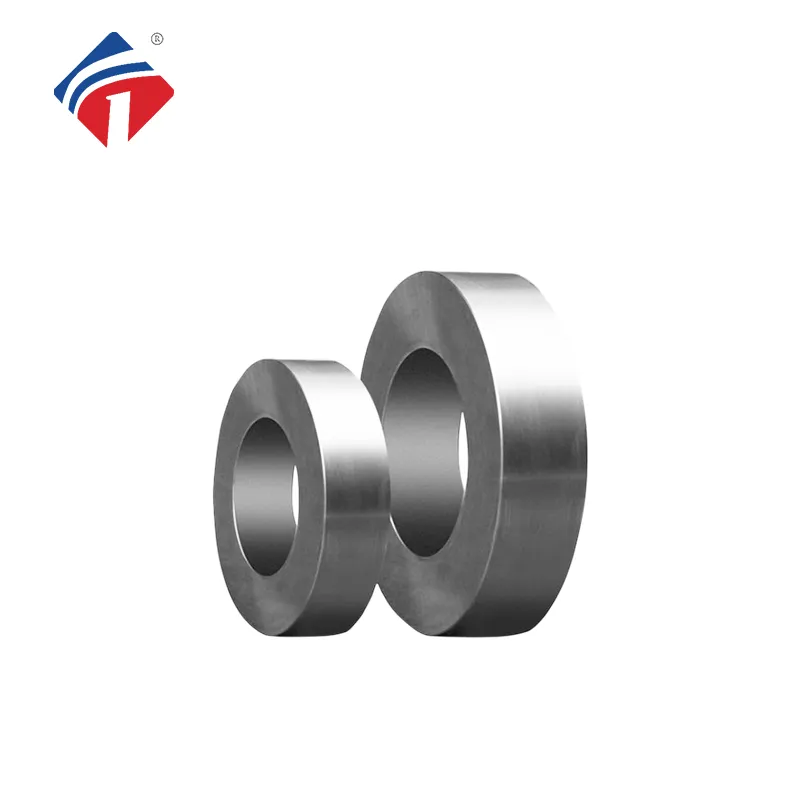

The science behind tyhightech’s carbide roll rings with tight tolerances for seamless tube mills is impressive. Made from premium materials, they boast incredible toughness and resistance to wear. Their advanced design handles stress like a champ.

Unlock innovation with tyhightech. Our carbide roll rings with tight tolerances for seamless tube mills showcase engineering brilliance, offering unmatched reliability. Equip your mill with the best in modern technology.

In the manufacturing of structural steel shapes, tyhightech’s carbide roll rings with tight tolerances for seamless tube mills provide the strength needed for heavy-duty rolling. These rings handle the intense forces of shaping beams and channels, ensuring precise dimensions and surface quality. Their durability makes them a staple in construction and infrastructure projects.

Choose tyhightech for roll rings that power structural steel production. Their advanced materials resist wear and deformation, ensuring consistent performance. With tyhightech, you get tools that combine precision and toughness, helping you build the future with confidence.

Sustainability is reshaping the industry, and tyhightech’s carbide roll rings with tight tolerances for seamless tube mills are riding the wave. Recyclable materials and eco-conscious production methods are in demand, reducing waste without sacrificing strength. These rings last longer, cutting down on replacements and environmental impact. tyhightech blends green practices with top performance, making it easy to roll sustainably. Embrace this trend and show the world your commitment to a cleaner future.

Sustainability is the future of rolling. tyhightech’s carbide roll rings with tight tolerances for seamless tube mills are made with eco-friendly processes, cutting emissions and waste. Their long lifespan reduces the need for frequent replacements, saving resources in high-volume steel rolling. It’s a green solution that doesn’t compromise on strength.

These rings excel in tough conditions, from hot rolling to precision tasks, with minimal maintenance. Their recyclable materials make end-of-life management simple. Embrace these eco-conscious tools to roll out quality while supporting a sustainable industry.

Future-ready design defines tyhightech’s carbide roll rings with tight tolerances for seamless tube mills. Advanced materials prepare them for tomorrow’s demands. Stay ahead with forward-thinking components.

Invest in tyhightech for the long haul. Our roll rings adapt to evolving needs, keeping you competitive. Embrace what’s next with confidence.

Q: Are they suitable for all rolling mills?

A: They work with most systems, though adjustments to cooling or lubrication might be needed for optimal integration.

Q: What’s the price range for these roll rings?

A: While they cost more initially than traditional materials, their longevity and reduced upkeep expenses often offset the investment.

Q: How do they contribute to long-term savings?

A: Their extended lifespan and minimal maintenance needs cut down on replacement frequency and operational interruptions, lowering overall costs.

Q: Do manufacturers provide warranties for them?

A: Most suppliers offer warranties covering material or manufacturing defects, though terms differ by provider.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

Although the initial cost is higher, the long lifespan and reduced replacement frequency make these rolls a cost-effective solution.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

What is the typical lead time for delivering cemented carbide rolls? We have an urgent requirement a...

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

Copyright © Tian Yi All Rights Reserved