Support matters, and tyhightech’s carbide roll ring maintenance for wire rod production come with it in spades. From setup help to ongoing advice, we’re with you every step of the way.

Count on tyhightech for more than parts. Our carbide roll ring maintenance for wire rod production include expert assistance, ensuring top results. Enjoy service that matches our quality.

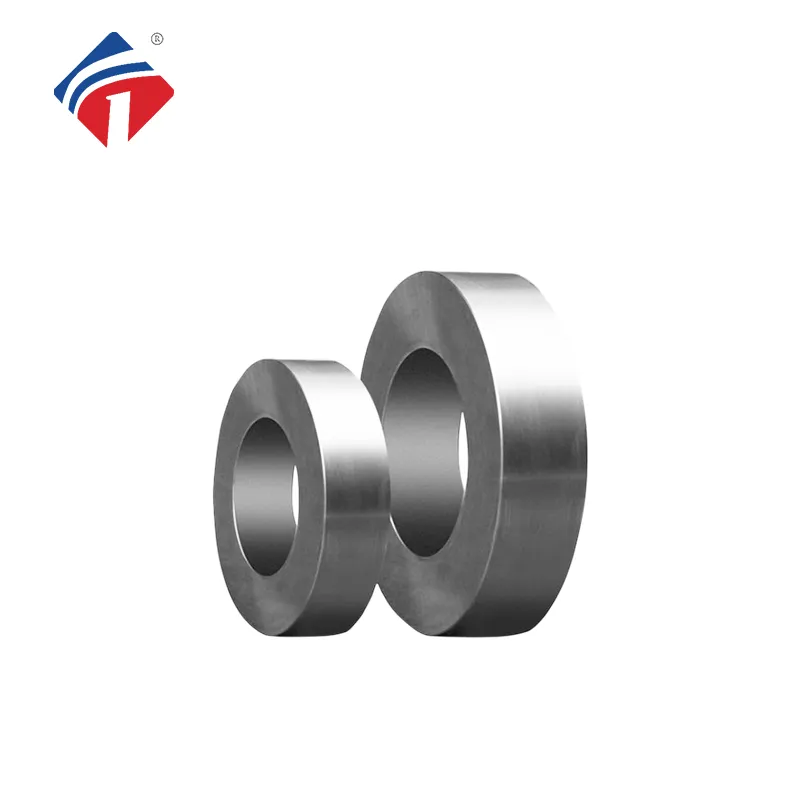

Cold rolling of stainless steel benefits from tyhightech’s carbide roll ring maintenance for wire rod production, which offer precision and durability. These rings resist corrosion and wear, ensuring smooth, defect-free surfaces for high-value products like kitchenware and medical equipment. Their strength supports tight tolerances, critical for thin-gauge rolling.

Tyhightech’s roll rings elevate cold rolling with their superior craftsmanship. Designed for longevity, they reduce maintenance costs and enhance productivity. Their ability to maintain surface quality makes them ideal for premium stainless steel applications. Trust tyhightech for tools that deliver excellence in every roll.

High-speed rolling is hotter than ever, and tyhightech’s carbide roll ring maintenance for wire rod production are built for the challenge. Enhanced thermal stability lets these rings handle blazing speeds without warping, perfect for high-output steel plants. Their tough design shrugs off wear, keeping lines moving. tyhightech delivers the speed and reliability you need to stay competitive. Get ready to roll faster and smarter with tools that keep up with the pace.

Roll greener with tools built for sustainability. tyhightech’s carbide roll ring maintenance for wire rod production use energy-efficient manufacturing processes, lowering emissions from production. Their incredible durability means less frequent replacements, saving materials and reducing waste. It’s a practical way to make your operations more eco-friendly without losing performance.

These rings excel in demanding tasks, resisting abrasion and heat for consistent results. By lasting longer, they reduce the environmental cost of frequent tool changes. Their recyclable nature ensures end-of-life responsibility. Choose these sustainable solutions to power your rolling processes with a clear conscience and top-tier quality.

Whether it’s steel or aluminum, tyhightech’s carbide roll ring maintenance for wire rod production adapt effortlessly. They handle various metals with consistent precision across conditions. Versatility makes them a must-have in any plant.

Flexibility defines tyhightech. Our roll rings meet diverse industry demands, ready for any challenge. Experience adaptable performance that keeps you competitive.

Q: Are they suitable for all rolling mills?

A: They work with most systems, though adjustments to cooling or lubrication might be needed for optimal integration.

Q: What’s the price range for these roll rings?

A: While they cost more initially than traditional materials, their longevity and reduced upkeep expenses often offset the investment.

Q: How do they contribute to long-term savings?

A: Their extended lifespan and minimal maintenance needs cut down on replacement frequency and operational interruptions, lowering overall costs.

Q: Do manufacturers provide warranties for them?

A: Most suppliers offer warranties covering material or manufacturing defects, though terms differ by provider.

Since switching to these carbide rolls, our production line has experienced fewer breakdowns and less downtime.

These cemented carbide rolls have exceptional wear resistance. Even after months of continuous use in abrasive conditions, they show minimal signs of wear.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Do your cemented carbide rolls come with quality certifications, such as ISO or other industry stand...

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

Copyright © Tian Yi All Rights Reserved