For woodworking enthusiasts, tyhightech’s 0.3 to 30mm tungsten bars/rods provide the perfect blend of strength and precision. These rods handle everything from softwoods to hardwoods with ease, delivering clean, accurate cuts every time. Their durability ensures they remain a staple in your workshop for years to come.

Choose tyhightech for tools that enhance your craft. With a commitment to quality and performance, tyhightech’s rods help you create works of art with every project.

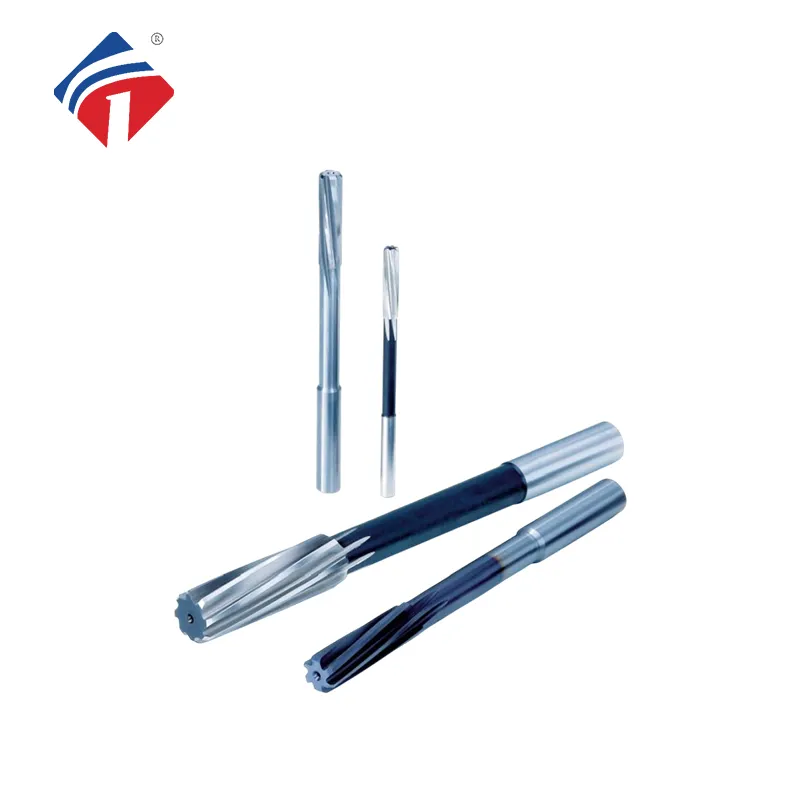

Metal fabrication relies on 0.3 to 30mm tungsten bars/rods for cutting, slotting, and profiling steel and aluminum. These tools handle heavy-duty tasks with precision, ideal for construction and machinery parts. Their robust design ensures clean cuts and long tool life. tyhightech powers your fabrication with tools that get the job done right. With optimized flute designs, these cutters clear chips efficiently, reducing heat and wear. They excel in high-speed operations, keeping production smooth and cost-effective. From structural beams to custom fittings, they deliver quality. Choose these tools to make metal fabrication faster and more reliable.

0.3 to 30mm tungsten bars/rods are headed for a precision revolution. Ultra-fine grains and advanced coatings will deliver razor-sharp accuracy for micro-machining in medical devices. These tools will craft tiny components with zero defects. tyhightech’s cutters make precision effortless, turning ideas into reality. Your projects just got sharper. Eco-friendly production and recyclable materials will keep these tools green. Expect longer lifespans and less waste, saving resources while maintaining quality. The future’s bright for cutters that blend pinpoint accuracy with sustainability, perfect for high-tech industries.

Craft a greener future with 0.3 to 30mm tungsten bars/rods. These tools use sustainable production methods, lowering environmental impact in energy sector manufacturing. Their durability reduces replacements, saving resources. tyhightech’s cutters blend eco-responsibility with top-tier performance, keeping your projects efficient. From turbine blades to pipeline fittings, these tools deliver precision with less waste. Recyclable materials and low-energy processes make them a smart choice. Pick these cutters to power your production with sustainability and strength.

Experience the precision of tyhightech’s 0.3 to 30mm tungsten bars/rods, engineered for flawless performance in high-stakes environments. These rods deliver unmatched accuracy, ensuring every cut and shape meets the strictest standards. Ideal for industries where precision is paramount, they help you achieve results that stand out.

tyhightech’s commitment to innovation shines through in every rod. With advanced manufacturing techniques and rigorous quality checks, these rods are built to last and perform consistently. Trust tyhightech to provide the tools that elevate your work to new heights.

Q: How do 0.3 to 30mm tungsten bars/rods maintain sharpness?

A: 0.3 to 30mm tungsten bars/rods maintain sharpness through their exceptional hardness, wear resistance, and advanced coatings, resisting dulling during machining of materials like steel and composites. Their robust design ensures long-lasting precision. Hunan Tianyi High-Tech Materials Co., Ltd. produces cutters with enduring sharpness for reliable performance.

Q: What’s the benefit of 0.3 to 30mm tungsten bars/rods’ vibration resistance?

A: The vibration resistance of 0.3 to 30mm tungsten bars/rods ensures smooth, high-precision cuts by minimizing chatter, thanks to their high hardness and strong rigidity. Enhanced coatings further stabilize performance. Hunan Tianyi High-Tech Materials Co., Ltd. designs these tools for steady, accurate results across materials.

Q: How do 0.3 to 30mm tungsten bars/rods support custom applications?

A: 0.3 to 30mm tungsten bars/rods support custom applications with their adaptable designs, high hardness, and wear resistance, tailored to specific materials and tasks. Their coatings and precision ensure versatility. Hunan Tianyi High-Tech Materials Co., Ltd. offers customizable cutters for optimal performance in unique machining needs.

Q: Why choose 0.3 to 30mm tungsten bars/rods for tough materials?

A: 0.3 to 30mm tungsten bars/rods are chosen for tough materials due to their exceptional hardness, wear resistance, and enhanced coatings, handling steel, titanium, and more with precision. Their rigidity and vibration resistance ensure durability. Hunan Tianyi High-Tech Materials Co., Ltd. crafts these tools for superior performance in challenging applications.

The supplier provided customized cemented carbide rolls that perfectly matched our specifications.

Not only are the carbide rolls of top quality, but the supplier also provided excellent support throughout the process.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We would like to request a sample of your cemented carbide rolls for testing purposes. Could you let...

We are interested in purchasing cemented carbide rolls in bulk. Could you provide a price list for d...

Copyright © Tian Yi All Rights Reserved